2500 automatic tank gauge installation and operations manual

EVO 200 and EVO 400 Automatic Tank Gauges Installation

EVOTM 400 Automatic Tank Gauge (ATG). You must follow all safety information, warnings, instructions, and other information in this manual. Please read this entire manual carefully. If you do not follow the instructions in this manual, the result could be faulty operation, equipment damage, injury, or death. Questions and concerns

No. 20 Tokheim Tank Gauge Installation Instructions STEP 1

No. 20 Tokheim Tank Gauge Installation Instructions STEP 3 (a) Remove covers from Housings 20A and 20C and Elbow 20H. Detach outer end of measuring tape, insert pencil in center of cardboard spool, and starting at Elbow 20H push measuring tape down through Pipe 3 and Reading Section 20GX.

Installation Instructions Residential Oil Tanks, Septic

Installation Instructions For Single and Multiple Tank Applications Section 4 Interior Single Tank Installation The secondary containment tank is made with 19 gauge galvanized steel. The use of steel offers strength to resist damage to the inner tank from Figure 1.1.

Varec 2500 Installation And Operation Manual

Page 66 2500 Automatic Tank Gauge Installation and Operations Manual Page 67: Operation 3. Turn the crank counter clockwise to raise the float about 2 inches (51 mm) above the prod uct, then lower it back to the surface. The float should not be left on the surface of prod ucts that are agitated.

Applying Tank Farm Safety Standards for Petroleum Storage

Applying Tank Farm Safety Standards for Petroleum Storage Tanks in India . S. K. Ravindran, National Sales Manager, Honeywell Enraf . John Joosten, Global Product Manager, Safety & Radar, Honeywell

Duramax Diesel Manual Chevrolet

the owner manual for phone numbers to assist you in contacting a GM dealer. See Recommended Fluids and Lubricants on page 11 8. As the DEF tank becomes low on fluid, warnings begin with approximately 1600 km(1,000 mi) of remaining range. These warnings will increase in intensity as the tank becomes empty. Once the tank is empty, the vehicle

The Art of Tank Gauging ICEweb

involved in tank gauging. Reliability to prevent product spills and safety of the environment and personnel are equally important. The following listings show a number of requirements for Tank Gauging Systems. 1.2 Why Tank Gauging? Tank Gauging is required for the assessment of tank contents, tank inventory control and tank farm management.

INSTALLATION & OPERATION MANUAL Milton Roy

INSTALLATION & OPERATION MANUAL DAMPENER (CHARGEABLE MODEL) Dampeners are pressure vessels containing a flexible bladder or bellows inside that separates an inert pressurized gas (air or Nitrogen) from a system fluid in the lower chamber.

REMANUFACTURED INSTRUMENT CLUSTERS Dorman

REMANUFACTURED INSTRUMENT CLUSTERS READY TO INSTALL • Fully programmed: calibrated mileage Yukon XL 1500/2500, 6 Gauge w/chrome, PRND321 *Available in US only. [CHRYSLER] 599 504 599 311 2005 03 GM Silverado SS White Face Gauge (w/ Sport Package, Automatic Transmission) 599 312 2005 02 Impala Exc. Police, w/ Tachometer,

Automatic Tank Gauge No. 30 OCECO

The OCECO 30 62 Automatic Tank Gauge is engineered to provide the utmost in long, dependable, trouble free gauging. This highly efficient tank gauge has proven to be exceedingly accurate during laboratory tests conducted in conformance to standards set by the A.P.I. gauging committee, and in tanks under actual service conditions.

DESIGN, INSTALLATION, OPERATION AND

DESIGN, INSTALLATION, OPERATION AND MAINTENANCE MANUAL FOR PRE ENGINEERED AUTOMATIC INDIRECT FM 200 installed, before removing the cylinder from the installation, and before performing any charging, leak tests or salvage operations. 5. Follow all of the safety procedures included on the cylinder nameplate and in this manual.

Spraymaster Deaerator Boilermate Deaerator

°F thermometer, and a water level gauge glass (or glasses). The main deaerating portion is located internally and consists of a water collector and steam atomizing valve. Built into a flange on the top of the tank is a spring loaded spray nozzle inlet water assembly that includes an automatic vent valve and a manual vent valve.

INSTALLATION AND OPERATION MANUAL CENTRIFUGAL

INSTALLATION AND OPERATION MANUAL CENTRIFUGAL PUMPS IMPORTANT! Read all instructions in this manual before operating pump. As a result of Crane Pumps & Systems, Inc., constant product improvement program, product changes may occur. As such Crane Pumps & Systems reserves the right to change product without prior written notifi cation.

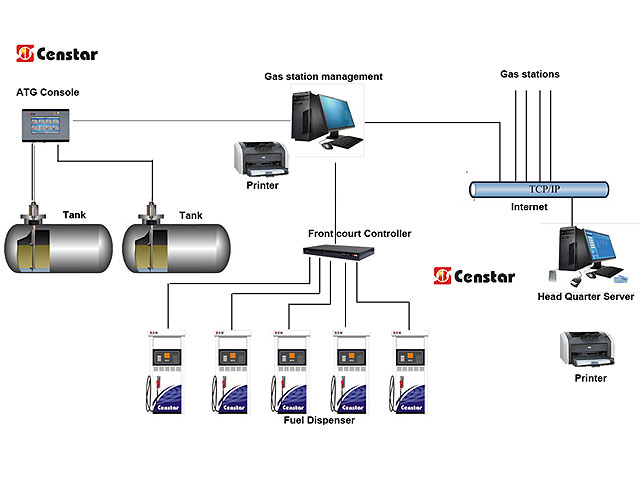

Tank Gauging System Emerson US

Tank gauging means liquid measurement in large storage tanks to determine product volume. Rosemount™ Tank Gauging System ensures accurate level, temperature, and pressure measurements for inventory control, oil movement and overfill prevention, securing efficient operations.

INSTALLATION & OPERATING INSTRUCTION MANUAL

INSTALLATION & OPERATING INSTRUCTION MANUAL. 2 This installation, operation and instruction manual will explain in detail the installation and maintenance of your new Electric Water Heater. We strongly recommend that A sacrificial anode is used to extend tank

TLS 350 Automatic Tank Gauge Veeder Root

TLS 350 Automatic Tank Gauging System A legacy of reliability With over 20 years of global experience as the most installed automatic tank gauge in the industry, the TLS 350 Automatic Tank Gauge provides users with a highly flexible design for meeting compliance and fuel management needs.

Motherwell Tank Protection Downloads

Motherwell Tank Protection Downloads. Breather Valve Datasheets. Gauge hatches allow easy access to atmospheric and low pressure liquid storage tanks for manual level measurement (dipping), temperature measurement and sampling. Low Pressure Automatic Tank Float Gauge providing accurate, continuous measurement of the tank level.

Manual Tank Gauging for Small Underground Storage Tanks

manual tank gauging: Manual tank gauging can be used only on tanks 2,000 gallons or smaller. Tanks 1,000 gallons or smaller can use this method alone. Tanks from 1,001 to 2,000 gallons can use manual tank gauging only when it is combined with periodic tank tightness testing. The combined method of manual tank gauging and tank tight

Installation and Operation Manual Livorsi Marine

Installation and Operation Manual NMEA 2000® SAE J1939 SmartCraft® Livorsi Marine, Inc. 715 Center Street Grayslake, IL 60030 USA Toll Free:

INSTALLER'S MANUAL CLEAN BURN

Installer's Manual: Clean Burn J Pump 1 Guidelines for Oil Pump Installation Before proceeding with the installation of the J pump, review the following guidelines for safe and proper tank/pump installation and operation: INSTALL THE VACUUM GAUGE IN ONE OF THE GAUGE PORTS ON THE OUTLET SIDE OF THE FILTER.