cargo vapour recovery system

Cargo Tank Vapor Recovery Fact Sheet California Air

The California Air Resources Board (CARB) was granted authority by the Health and Safety Code (HSC) § 41962 to adopt Title 17 CCR § 94014, the

MARICOPA COUNTY AIR POLLUTION CONTROL

214 STAGE 1 VAPOR RECOVERY SYSTEM (VR SYSTEM): Any piping, hoses, equipment, and/or devices which are used to collect, store, or process gasoline vapors displaced by the loading of gasoline and also by the onloading of gasoline into a vapor laden gasoline cargo tank. 215 SUBMERGED FILL: Any discharge pipe or nozzle which meets the applicable

Vapor Recovery Central Vacuum System

The California government agency that sets regulations for vapor recovery systems. Check Valve A mechanical device that normally allows fluid to flow through it in only one direction. Condensate Trap The low point in a vapor line where liquid may be present. EO = Executive Order

State of Oregon: AQ Programs Gasoline Vapor Recovery Program

DEQ also requires tankers to connect vapor recovery equipment when delivering gasoline at dispensing facilities. Gasoline dispensing facilities Gas stations and other dispensing facilities are subject to National Emission Standards for Hazardous Air Pollutants rules put into law by the U.S. EPA and adopted by DEQ (OAR 340 Division 232, 242, and

Bottom Loading and Vapor Recovery System Emco Wheaton

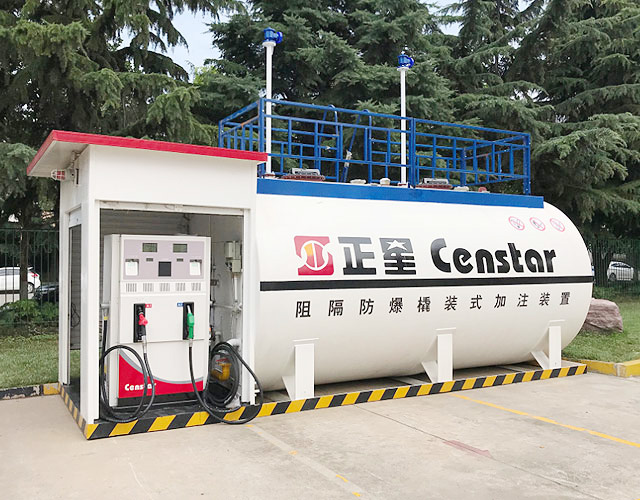

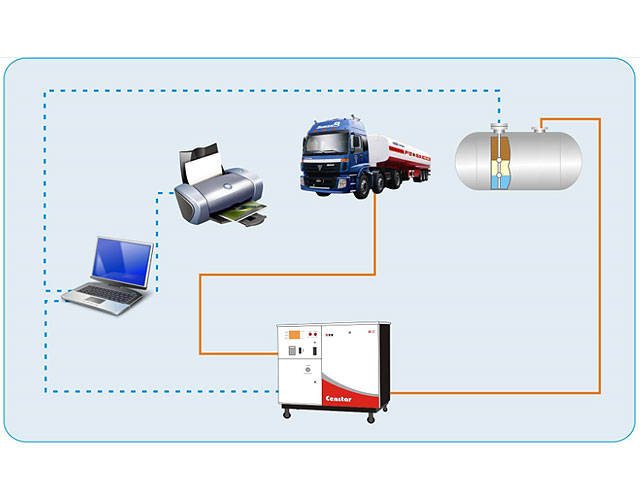

The advantages of bottom loading are well proven, with most oil companies having standardized on the practice internationally. The benefits of a Vapor Recovery System are that it is safer, faster, cleaner and provides the ability for vapor return, vapor reduction, cost reduction, and closed filling.

CARGO VAPOUR RECOVERY SYSTEMS DNV GL

This Classification Note gives requirements for cargo vapour recovery systems required to be fitted for class notation VCS 3 according to the Rules for Classi fication of Ships Pt.6 for recovery systems based on the following working princi ples: — re absorption of cargo vapours in the liquid cargo itself — liquefaction of cargo vapours

DNVGL CG 0042 Cargo vapour recovery systems

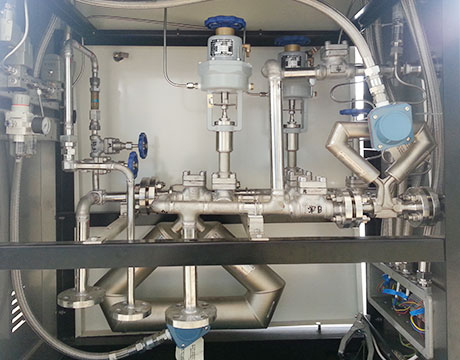

Cargo vapour recovery systems DNV GL AS SECTION 6 SYSTEM ARRANGEMENTS 1 Arrangements The temperature of flammable gas or liquid in any vapour recovery system shall not exceed 220oC, unless means are provided to prevent auto ignition in the event of gas or liquid leakages. This may be achieved

EcoVapor Recovery Systems ZerO2 Sell More Gas

Reduce Flaring with the ZerO 2 Vapor Recovery Solution. EcoVapor’s ZerO 2 systems focus on pulling vapors directly from oil storage tanks to enable 100% gas capture on site. EcoVapor has the right size system to match the unique characteristics of your wellsite. Our systems can function stand alone, in parallel with one another, or in conjunction with low pressure separation and/or vapor

Day 2 topic 4 Vapour Recovery Systems Стр 2

Vapour recovery system equipment and calculations To ensure that this is met it is very important that, at the pre cargo operations meeting with the shore terminal staff, there is agreement on the liquid loading rate and the expected pressure at the vapour connection.

Tank Vapor Recovery Safety in Design LBCG

VRU System Design Best Practices Piping should be sized to limit pressure drop to 0.5” w.c. between compressor suction and all equipment connections, at a minimum of two times nominal

Tanker Truck Certification (Vapor Recovery) Maricopa

Tanker Truck Certification (Vapor Recovery) To comply with this requirement, a gasoline delivery vessel shall first pass the Maricopa County Pressure Test before delivering or onloading gasoline, and must pass the test each year thereafter. All testing done within Maricopa County must comply with Section 401.1 concerning notification

Vapor Recovery Unit Capture/Control Guidance

3. Is there a system in place to ensure that no oxygen is allowed to be pulled into the system, such as a gas blanketing system? This form is for use by facilities subject to air quality permit requirements and may be revised periodically. New Vapor Recovery Units Efficiency Calculation Guidance/Charts (Revised 02/12) Page 2 of 5

Gas Compression and Vapor Recovery Systems Aereon

Carbon Bed Vapor Recovery Unit (VRU) Hundreds of customers around the world rely on AEREON liquid ring and dry vacuum based VRU systems that economically recover a variety of VOCs in truck, rail, marine storage and loading applications. AEREON also provides comprehensive service support for carbon VRUs, including other manufacturers’ brands.

1. Need for Tanker Vapor Recovery JFE Eng

9High Recovery Rate : 95% 9Compact & Simple Plant Configuration 9Wide Selection of Absorbent AL, AXL, AM & AH 9Pre Absorption Process VOC is absorbed to Absorbent. 9Membrane Separation Process Enrich VOC content of recycle gas. 9The process was developed in 1980s by JFE 9A lot of track records for gasoline vapor.

PURGIT REFRIGERATED VAPOR RECOVERY SYSTEM

Recovered Cargo PURGIT Mobile VRU Storage Tank, Tank Barge, etc. Liquid Nitrogen PURGIT Closed Loop Vapor Control System Detail of mixing action resulting from return vapors Vapor Condenser Control Device No Scale Plan View US Patent Office Patent Pending PURGIT REFRIGERATED VAPOR RECOVERY SYSTEM † Inert Tank Degassing † Nitrogen Tank Padding

Vapor Control System (VCS) Section

Vapor Control System (VCS) Section. For the most current information, please visit the VCS page on Homeport: Introduction: Since 1990, various Federal and State regulations have been enacted requiring certain marine transfer facilities to control their volatile or hazardous cargo vapor emissions.

Vapor Recovery Services Energy SGS

Vapor recovery units reduce these losses, providing both financial benefits through reclaimed product and environment benefits through reduced volatile organic carbon (VOC) emissions. Our vapor recovery services help you to ensure that your vapor recovery systems are working effectively.

Developing an effective crude oil vapor recovery system

One case by way of example is the crude oil vapor recovery system operating at Statoil’s Mongstad facility. For this system the VRU is required to recover vapors from up to four different crude oil types, with wide ranging compositions and vapor pressures, although the system can handle a much wider range of oil compositions.

Changes in the Vapor Recovery Program

The federal Vapor Recovery Program requires TMB person nel to witness testing of the vapor recovery system once ev ery three years. In addition, the federal UST Compliance Act of 2005 requires that facili ties, except those that have only heating oil USTs, be inspected for com pliance every three years. So, in

Vapor recovery Wikipedia

Vapor recovery is also used in the chemical process industry to remove and recover vapors from storage tanks. The vapors are usually either environmentally hazardous, or valuable to be recovered. The process consists of a closed venting system from the storage tank ullage space to a vapor recovery unit (VRU) which will recover the vapors for return to the process or destroy them, usually by oxidation.