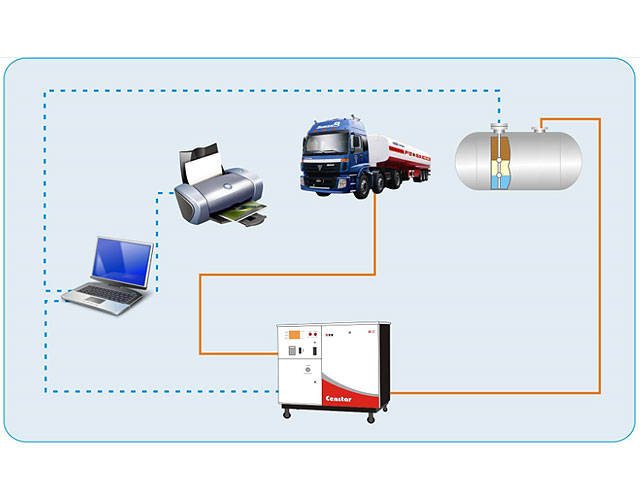

Piping type Management system of oil depot

Piping Type Management System of Oil Depot

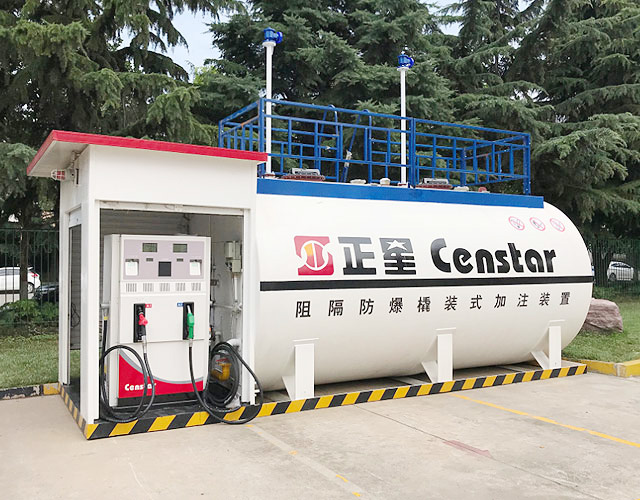

Automation System Online Edition Fuel Card System Censtar Cloud System Vehicle Identification system Automatic Tank Gauge Tank Calibration System TANKER SOLUTION Vehicle Mounted Dispenser Vehicle Mounted Hose Reel Automatic Tank Gauge Management Software OIL DEPOT SOLUTION Piping Type Centralized Type (for Diesel Only) SKID MOUNTED EQUIPMENT

Gas Station Complete Solution

AUTOMATION CONTROL SYSTEM TANKER SOLUTION OIL DEPOT SOLUTION SKID MOUNTED EQUIPMENT SPECIAL FILLING DISPENSER CONTACT US +86 371 67989006 [email protected] +86 371 67983787 No. 4, Xuesong Road, Hi new Technology Development District, Zhengzhou 450001, Henan, P.R. China.

Oil and Gas Pipelines and Piping Systems 1st Edition

Oil and Gas Pipelines and Piping Systems: Design, Construction, Management, and Inspection delivers all the critical aspects needed for oil and gas piping and pipeline condition monitoring and maintenance, along with tactics to minimize costly disruptions within operations. Broken up into two logical parts, the book begins with coverage on pipelines, including essential topics, such as material selection, designing for oil and gas central facilities, tank farms and depots

ENGINEERING STANDARD FOR PIPING MATERIAL SELECTION

API 601 “Metallic Gasket for RaisedFace, Pipe Flanges and Flanged Connections (Double Jacketed Corrugated and Spiral wound)” API 602 “Compact Steel Gate Valves Flanged, Threaded, Welding and Extended Body Ends” API 609 “Butterfly valves, Lug Type and Wafer Type” API 6D “Pipeline Valves (Gate, Plug, Ball and Check Valves)”

An Introduction to Petroleum Fuel Facilities: Piping Systems

1 Small diameter (≤4 inches (100mm)) pipe associated with the aboveground storage of fuel/oil shall be single wall aboveground piping. Exemptions may be granted by the Owner in cases where routing aboveground could result in catastrophic damage to the pipe.

Total Oil Management Cooking Oil Recycling Automated

Total Oil Management. All grease picked up the by our trucks is recycled into biodiesel, making used cooking oil removal and grease recycling easy for you and your business. The entire process is done according to your schedule and cooking oil usage, creating a seamless experience thanks to the system's closed loop functionality.

Oil management in a refrigeration system Carly : the

In a circuit with several compressors in parallel (rack assembly), the oil management system must be designed according to the application. For example, a multi compressors installation for a supermarket will not work the same way as the installation of a refrigerated warehouse.

Guide on How to Choose the Right Plumbing Pipe

Cast iron plumbing pipes are normally manufactured as bell and spigot type. It can also be found with threaded joints but are more expensive than the bell and spigot one. These pipes are heavier than any other pipes, normally used for water distribution systems, or underground installation as the main pipe on drainage or sewer systems. The smallest size that normally is manufactured is 4” pipe,

Oil and gas production handbook ed2x1 Welcome to Dr

Soon, oil had replaced most other fuels for motorized transport. The automobile industry developed at the end of the 19th century, and quickly adopted oil as fuel. Gasoline engines were essential for designing successful aircraft. Ships driven by oil could move up to twice as fast as their coal powered counterparts, a vital military advantage.

Terminals and Storage Facilities PetroSkills Oil and Gas

Throughout his years with Brown & Root (now KBR), Han Padron Associates (now CH2M Hill), and as an independent consultant, Mr. Gilad has been involved in the design and installation of numerous single point mooring (SPM) systems and other offshore petroleum terminals, fixed berth and offshore cargo transfer systems, oil and gas pipelines, Pipeline End Manifolds (PLEMs), pig launching/receiving and

Pipeline Integrity Management Programs NACE Edmonton

Document: “Guidance for corrosion management in oil and gas production” Developed by a industry working group Describes programs similar to Annex N “Corrosion management has been defined as part of the overall management system that develop, implements, reviews and maintains the corrosion management policy

Håvard Devold Oil and gas production handbook An

The valve can be used to determine leaks in casing, tubing or the packer, and is also used for lift gas injection into the casing. The tubing hanger (also called a donut) is used to position the tubing correctly in the well. Sealing also allows Christmas tree removal with pressure in the casing. Master gate valve.

Installation, Inspection, Maintenance, and Repair

The installer is responsible for pressure testing, installation inspection, performance testing, and acceptance testing. Installation must be performed by qualified personnel of the manufacturer or mechanical subcontractor or a SLAC pressure system mechanic. After installation is complete, a pressure test must be performed and documented.

Final Crude Oil and Petroleum Product Terminals

The EHS Guidelines for Crude Oil and Petroleum Product Terminals include information relevant to land and shore based petroleum storage terminals receiving and dispatching bulk shipments of crude oil, gasoline, middle distillates, aviation gas, lube oil, residual fuel oil, compressed natural gas (CNG), liquid

Facilities Instructions, Standards, and Techniques Volume

FIST 4 1A Maintenance Scheduling for Mechanical Equipment 17 Rotary positive displacement pumps are used in a variety of applications, one of the most common being hydraulic systems. Gear, vane, radial piston, and axial piston pumps (figure 6) are some of the most common rotary pumps used in

Best Oil and Gas Software 2019 Reviews of the Most

The system provides software for oil and gas land management, including due diligence, lease management, lease analysis, and runsheets. Learn more about Equisition. The system provides software for oil and gas land management, including due diligence, lease management, lease analysis, and

Pipeline integrity management software Pipeline risk

All pipeline data saved in one central data management system within the pipeline integrity management software; Enables compliance to best practice industry standards and codes for pipeline integrity; White box modelling and risk analysis; Efficient analysis of large

DNV OS D101: Marine and Machinery Systems and

DNV OS D101 MARINE AND MACHINERY SYSTEMS AND EQUIPMENT Classes of Piping systems in line with Rules for classification of ships Pt.4 Ch.6. — D. Fuel Oil System: — Included acceptance criteria for use of oil fuels with a flash point less than 60°C, in line with Rules for

Liquid Petroleum TM Argonne National Laboratory

The U.S. liquid petroleum pipeline industry is large, diverse, and vital to the nation’s economy. Comprised of approximately 200,000 miles of pipe in all fifty states, liquid petroleum pipelines carried more than 40 million barrels per day, or 4 trillion barrel miles, of crude oil

Pressure Tanks Well Pumps & Systems The Home Depot

The Everbilt Jet/Tank system comes with a 1/2 The Everbilt Jet/Tank system comes with a 1/2 HP shallow well jet pump manufactured of heavy duty cast iron for durability. The unit is pre wired for 115 / 230 Volt operation and is factory pre set at 230 Volt. The motor is

Oil management in a refrigeration system Carly : the

Some principles of oil return management are described hereafter. b 1 : Oil return at suction. A common oil separator for all the compressors is connected to the discharge collector of the rack. The oil return is made in the suction collector. The oil present in the suction collector is sucked by the compressors.

Guidelines For Choosing A Pipe Thread Sealant Plant

Looking into any maintenance technician’s tool box or a plant’s supply closet likely turns up some type of pipe thread sealant. But reaching for the nearest pipe joint sealing material can lead to serious problems, including leaks, pipe system damage, contamination, and plant downtime.

PROJECT STANDARDS AND SPECIFICATIONS piping and in

Size and type are based on the following: Alloy piping: DN 20 (¾ inch) gate valve with blind flange; Carbon steel piping: DN 20 (¾ inch) gate valve with threaded plug; The vent provided for hydrostatic testing shall be DN 20 (¾ inch) boss with threaded plug.

PIPING Kalhour

A piping system generally comprises common components such as pipe, fittings, and valves; however, less common piping items may be required, such as strainers, hoses and hose couplings, steam traps, or interlocks. This second group, called piping specials, must carry an SP number as an identifying tag.

Pipe Liner Methods and Technologies Community

The pH of water, chemical composition, delivery pressure, water temperature, and material of the pipe are some of the factors that contribute to pipe deterioration. Low or changing water pressure or green residue at fixtures or drains of copper pipe systems can be some of the initial outward signs of deteriorated pipes.

.60 80 S SOLID OIL NOZZLE Supplies Depot

.60 80 S SOLID OIL NOZZLE .60 80 S SOLID OIL NOZZLE. You can shop at with confidence. We have partnered with a leading payment gateway since 1996, to accept credit cards and electronic check payments safely and securely for our customers.

Final Crude Oil and Petroleum Product Terminals

The storage and transfer of liquid materials in crude oil and. petroleum product ter minals creates the potential for leaks or. accidentally releases from tanks, pipes, hoses, and pumps. during loading and unloading of products.

Oil and gas production handbook ed1x3a5 comp NTNU

In a distributed production system this would be called the gathering system. The remainder of the figure is the actual process, often called the Gas Oil Separation Plant (GOSP). While there are oil or gas only installations, more often the well stream will consist of a full range of

What is a Tank Farm? Definition from Corrosionpedia

A tank farm is an area used mostly for the storage of oil and/or petrochemical products in large tanks. From the tank farm, petroleum products are distributed to end users or further storage facilities. Tank farms consist of: Gantries for the discharge of products into road tankers or other vehicles (such as barges) or pipelines.

Manual for On site Sewage Management Systems

This manual is divided into 16 sections: Section A provides the Rules of the Department of Public Health for On site Sewage Management Systems, Chapter 511 3 1." Section B covers the general soil provisions for on site sewage management systems. Chapter C discusses the role of soil information and use of soils in sewage treatment and disposal.

Environmental Construction Geosynthetic Liner Services

Environmental Construction, Inc. is based in Scott Depot, West Virginia. Our Geosynthetic Liner installation and repair crews operate from our location to across 500 mile radius. ECI as a company has over 169,000,000 million sq. ft. of experience all over the states of West Virginia, Virginia, Kentucky, Ohio, Maryland, Tennessee, Pennsylvania

Featured Article CRITICALITY ASSESSMENT OF PIPING

In Figure 4 it is clear that not all piping systems have the same importance for the plant, meaning that not all piping systems should have the same inspection frequency. Only 2% required a very well detailed inspection and integrity management pro gram. Figure 6 shows that just 18% of piping systems

Restaurant Technologies RTI Safer, Smarter Kitchens

Total Oil Management. With Total Oil Management, we handle the entire oil process for you—from ordering and receipt processing all the way to storing, handling and recycling of used oil. Our advanced kitchen technology even automates everything so your employees never have to worry about transporting hot oil ever again.

Integrated process plant management systems proliferating

Anne K. Rhodes Refining/Petrochemical Editor The proliferation of new integrated process plant management systems is changing the way petroleum processing plants operate while bolstering their

Guidelines For Choosing A Pipe Thread Sealant Plant

Looking into any maintenance technician’s tool box or a plant’s supply closet likely turns up some type of pipe thread sealant. But reaching for the nearest pipe joint sealing material can lead to serious problems, including leaks, pipe system damage, contamination, and plant downtime.

UFGS 33 08 55 Commissioning of Fuel Facility Systems

products. The following types of systems are covered: receipt systems, storage tank systems, transfer systems, hydrant systems, marine fueling systems, truck fillstands. For "Type III" Hydrant System commissioning, use Specification Section 15899 of DoD Standard Design Number AW 078 24 28. The designer should include the Contractor's /

Pipeline pigging PetroWiki

Pipeline cleanup. Operations may conduct pigging on a regular basis to clean solids, scale, wax buildup (paraffin), and other debris from the pipe wall to keep the pipeline flow efficiency high. In addition to general cleaning, natural gas pipelines use pigs to manage liquid

Featured Article CRITICALITY ASSESSMENT OF PIPING

Ensuring the integrity of process piping systems in the Oil & Gas industry (specifically those related to the ASME Code B31.3) is a key issue with respect to the process, business, safety, and the environment.

Flange management presentation SlideShare

1. Flange management Egyptian Maintenance Company 2. Course contents Module 1 Piping Specifications. Module 2 Flanges. Module 3 Gaskets. Module 4 Flange Bolting. Module 5 Management system . 3. Page 3 Plant piping Specifications The Piping Specification is a document prepared during the design phase of any project.

YOUR PETROLEUM STORAGE TANK FACILITY INSPECTION

underground piping systems, product leaked from the primary containment is directed toward an interstitial monitor located in the space between the primary and secondary containment walls. General Concerns About Leak Detection Inspect the system at least monthly and record the inspection results.

Stormwater Treatment Devices & Systems Water Quality

Water Quality. View Product FLEXSTORM Trash Capture Screens The FLEXSTORM Trash Capture line of Connector Pipe Screens (CPS) helps eliminate the flow of View Product Nyloplast Envirohood EnvironHood is an innovative stormwater management device attached to the inside of a catch basin View Product Nyloplast Water Level Control Structure Ideal

(PROJECT STANDARDS AND SPECIFICATIONS) Malaysia

NUMBERING SYSTEM (PROJECT STANDARDS AND SPECIFICATIONS) Page 5 of 45 Rev: 01 April 2011 Drivers for Main Equipment Drivers for main equipment shall be numbered as follows: Note: Type of drivers shall be as follows: DE : Diesel Engine GE : Gas Engine GT : Gas Turbine HT : Hydraulic Turbine M : Electric Motor ST : Steam Turbine TEX: Turbo Expander.

Locations Shawcor

Locations; Pipe Coating Solutions; Expertise End to End Systems Plant Capabilities Complete Coating Assurance HSE Management Systems Operational Excellence Risk Management Mobile Coating Technologies Pipeline Life Cycle Management Logistics & Preservation Program Integrated Solutions

Fuel / Petroleum Equipment & Supplies

Petroleum Equipment systems supplies & parts for fuels / biofuels / biodiesel / gasoline / diesel / oil handling (fuel transfer pumps fuel flow meters oil transfer pumps fuel nozzles filters tanks grease guns +

Method Statement HQ Construction Method Statements

Construction Method Statements & Documentation Portal. In addition to the basic project environmental health and safety management organization structure, the organization can setup an independent project safety committee to carry out the following functions: Discuss safety policies and recommend adoption of these by management.

PG 18 10 Plumbing Design Manual

This design manual shall be utilized for all VA projects, major, minor, and NRM including projects. It is expected that systems designed shall meet their primary intent of providing a sanitary, safe, reliable, and sustainable facility.

API Standards for Safe Offshore Operations

Testing of Basic Surface Safety Systems for Offshore Production Platforms Recommended Practice for Design and Installation of Offshore Production Platform Piping Systems Design, Installation, and Maintenance of Electrical Systems for Fixed and Floating Offshore Petroleum Facilities for Unclassified and Class I, Division 1, and Division 2 Locations

How do Oil Water Separators Work?

Many commercial and industrial businesses are required to use oil water separators to prevent adverse environmental effects and to maintain the health of municipal wastewater management systems. How do Oil Water Separators Work? The basic premise under which oil water separators work is

Construction of Bulk Oil Depot (Civil, Mechanical

Construction of Bulk Oil Terminal (Civil, Mechanical, Electrical & Instrumentation Works) at Mehmood kot. Scope of Work: The Scope of Work of this Contract consists of supply of all materials and construction of storage tanks, piping, equipment installation, buildings, oily water / storm water drain systems, roads, pavements, foundations

The Oil & Gas Supply Chain: Oil Tank Storage and Movement

The oil and gas supply chain is complex. One set of complexities involves tank farms. Achieving operational flexibility involves coordinating a large set of technologies and business functions. This article describes oil tank storage and movement best practices.

Types of Pipe Fittings in Plumbing System for Different

Various types of pipe fittings are available in plumbing systems for different purposes and functions. A pipe fitting is used in plumbing system to join multiple pipes of same size or different sizes, to regulate the flow or to measure the flow.

How do Oil Water Separators Work?

Oil water separators are used in a number of industrial application for the removal of oil, oil coated solids, grease, and light petroleum products from wastewater. This wastewater is then discharged into municipal sewer systems.

API Standards for Safe Offshore Operations

Production Platform Piping Systems Design, Installation, and Maintenance of Electrical Systems for Fixed and Floating Offshore Petroleum Facilities for Unclassified and Class

Topic 9: Safety and risk management in oil and gas

Leading Oil and Gas Companies like shell, Chevron etc have well established safety and Risk management systems that ensures that the safety of their operations are guaranteed. These companies most often have invested billions over the years in safety related matters.

Useful Key Performance Indicators for Maintenance

5 planner would investigate the failure and identify the categories (there maybe more than one category) that influenced the failures. A pie chart or bar chart of work orders per category each month would be a good way to show this KPI.

Fuel Management Systems Centre Tank Services

Designed with the small to medium vehicle fleet in mind, CTS supply a range of fuel management systems and fuel management software. Available either as a retrofit unit without a pump or as a fuel management system with integrated fuel dispensing equipment, Piusi fuel monitoring systems provide the fleet operator with fuel tank security and tank monitoring capabilities, putting them in control of their

Managed Pressure Drilling (MPD) Schlumberger

Managed pressure drilling (MPD) provides a closed loop circulation system in which pore pressure, formation fracture pressure, and bottomhole pressure are balanced and managed at surface. In compliance with European Union (EU) legislation for visitors from the EU, Schlumberger requests your permission to place cookies on your computer to both

Energy Kinetics Hot Water Systems High Efficiency Oil

Start SAVING on your FUEL BILL with the leading energy efficient gas and oil boiler and hot water system. Energy Kinetics' commercial and residential boilers are high quality and backed by the industry's best warranty.

Fuel Tank Fill Point and Vent Equipment CTS

As a key supplier to many storage tank manufacturers, we have a large stock holding of a full range of tank fill point and vent equipment. Whilst we often supply these products at tank manufacturing stage, we also sell to the retrofit and replacement market.

Control of Major Accident Hazards Health and Safety

The Buncefield oil storage and transfer depot is a tank farm in Hemel Hempstead, Hertfordshire, England, close to Junction 8 of the M1 motorway. In December 2005 there were three operating sites at the depot: Hertfordshire Oil Storage Ltd (HOSL), a joint venture between Total UK Ltd and Chevron Ltd and under the day to day management of Total UK Ltd. HOSL (the

MSC Guidelines for Bilge and Ballast Systems

CFR 151 Subpart D by using a treatment system must install a type approved system in accordance with 46 CFR or a Coast Guard accepted Alternate Management System. (33 CFR ) Each ballast water management system (BWMS) must be designed with stop valves at the connection to the ballast piping system and a by pass valve or

Pipe Insulation for Oil & Gas Industry Perma Pipe Inc.

Subsea oil and gas pipelines and equipment often require insulation to maintain the oil or gas above a temperature where hydrate or paraffin formation can occur that would cause restricted or blocked flow and reduced oil or gas production. Perma Pipe’s AUTO THERM GSPU is specially formulated for an optimum combination of thermal performance