tank level measurement

Methods of Fluid Level Measurement in Industrial Processes

The need for accurate and reliable level measurement systems is increased by the demands of advanced automated processing systems, more stringent process control and strict regulatory requirements. By improving the accuracy of level measurement, the variability in chemical processes can be reduced

Closed Tank Level Measurement with a DP Transmitter

Closed Tank Level Measurement with a DP Transmitter. As seen from the calculation above, the effect of the gas pressure is cancelled and only the pressure due to the hydrostatic head of the liquid is sensed. The low side transmitter piping that provides the reference connection is called a dry leg condition.

Mechanical Level Measurement Gauges KENCO

Mechanical Level Measurement by KENCO. Versatile and Robust Mechanical Level Indication Solutions for Storage Tanks. 5700 Bulk Tank Level Gauge. 4400 Close Mount Level Gauge. 17000 Bulk Tank Level Gauge. ESP/ST Series Armored Level Gauge. Safeguard Level Gauge. EPG Environmental Protection Gauge.

Liquid Level Measurement Using Bubbler Method Brooks

Achieving level measurement of a liquid in a tank using a pressure transmitter to measure the pressure created by the weight of the liquid. The key feature of this method is the use of a small diameter (typically ¼") tube installed in the tank to allow the pressure measurement to be taken at the top of the tank, eliminating potential leak points at the bottom of the tank.

LNG Storage Tank Level Measurement Emerson Automation

The system includes 5900S non contacting radar level gauges, 2240S multi input temperature transmitters, and a 2410 tank hub which powers and collects data from the field units. This system is SIL 2 and SIL 3 certified for overfill prevention according to IEC 61508 Part 1 7 .

A Practical Overview of Level Measurement Technologies

This simple level measurement has a dip tube installed with the open end close to the bottom of the process vessel. A flow of gas (usually air) passes through the tube and when air bubbles escape from the open end, the air pressure in the tube corresponds to the hydraulic head of the liquid in the vessel.

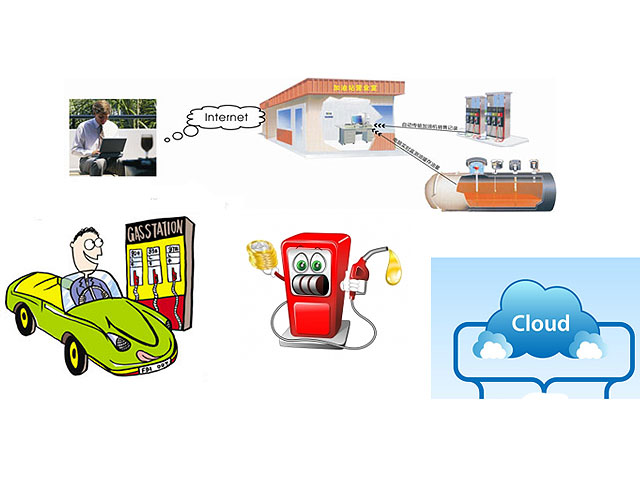

Tank Level Monitoring Banner

Wireless monitoring system for multiple tank level measurements that is easy to set up, interpret the results, & monitor locally through a cloud based system.

Level Measurement Omega Engineering

Radar Level Transmitters In applications requiring non contact measurement of liquid levels, the affordable LVRD500 radar transmitter is the logical extension of ultrasonic sensors. They are ideal where vapor, dust, or a foaming surface prevents ultrasonic measurement. Their radar sensor uses microwave pulse technology to track target liquids from the antenna tip to the bottom of a tank.

How to Calculate Tank Level Using Pressure Hunker

The tank is 96 inches high. The tank is elevated 6 inches off the ground on a pad to allow a plastic pipe to emerge from its bottom. An accurate zero to 10 pound per square inch (psi) pressure gauge reads exactly 3 psi. From this information, you can calculate the level.

Level measurement Endress+Hauser

Continuous level measurement and point level detection in liquids and bulk solids. Levels in liquids, pastes, bulk solids or liquefied gases are often measured in tanks, silos or movable containers. For continuous, interface and density measurement as well as for point level detection a broad range of measuring principles is available.

Level Measurement Emerson US

Level Measurement. Solve your level and interface challenges, see your solids volumes, and find the right product for your application needs with the Emerson TM portfolio of level measurement

Measuring Level By Measuring Pressure Water Online

Tank Level Measurement Capabilities Viatran uses a variety of pressure measurement techniques to determine liquid levels in different tank setups and applications. By measuring the hydrostatic head pressure at the bottom of a tank and the specific gravity of the liquid, the level in the tank

Tank Level Measurement

Mobile Tank Level: Everything is much more complicated with tanks of fluid mounted on vehicles or aircraft. The motion of the vehicle can result in sloshing of the fluid inside the tank, and this produces a noisy signal. In aircraft, the force from acceleration due to

Differential pressure in open tank level measurement

With level measurement based on hydrostatic pressure, the high pressure cell goes at the bottom of the tank. And in an open tank, the low pressure cell should be open to the air. Some companies sell gauge transmitters for open tanks.

Liquid level measurement Basics 101 Control Global

level measurement. The market estimate included continuous level devices which measure the continuous level of liquid or solids in a tank, as well as point level devices which measure liquids or solids at one or more points in a tank. This paper will focus on those devices used for liquid level measurement. Continuous level

Level sensor Wikipedia

Hydrostatic pressure level sensors are submersible or externally mounted pressure sensors suitable for measuring the level of corrosive liquids in deep tanks or water in reservoirs. Typically, fluid level is determined by the pressure at the bottom of the fluid containment (tank or reservoir); the pressure at the bottom, adjusted for the density / specific gravity of the fluid, indicates the depth of the fluid. [3]

A Dozen Ways to Measure Fluid Level and How They Work

Level measurement determines the position of the level relative to the top or bottom of the process fluid storage vessel. A variety of technologies can be used, determined by the characteristics of the fluid and its process conditions.

Level Measurement using DP Transmitters Working Principle

Level Measurement using DP Transmitters Working Principle for Open Tank and Closed Tank. Visit for more articles.

Flowline Liquid & Solid Level Sensors, Switches

Our quality solutions measure tank inventories, automate tank processes, ensure workplace safety and protect the environment. We design, manufacture and market the best level measurement and control instruments for your chemical, water, wastewater, oil and dry solid applications.

Tank Level Measurement Capabilities Viatran

Tank Level Measurement Capabilities Viatran uses a variety of pressure measurement techniques to determine liquid levels in different tank setups and applications. By measuring the hydrostatic head pressure at the bottom of a tank and the specific gravity of the liquid, the level in