vapour recovery system for gasoline

VOC recovery Systems IPIECA

Vapour recovery units. VRUs are equipped with a control pilot to prevent the creation of a vacuum in the top of the tank. Vapours are then metered and removed from the system for pipeline sale or onsite fuel supply. VRUs are capable of recovering more than 95% of

Vapor Recovery Unit VRU Package Unimac LP

VRUs (Vapor Recovery Units) are relatively simple systems that can capture about 95 percent of the Btu rich vapors for sale or for use onsite as fuel. Recovered vapors contain natural gas liquids, that have a Btu content that is higher than that of pipeline quality natural gas (between 950 and 1,100 Btu per standard cubic foot [scf]).

Three Reasons Why You Should Not Top Off the The Gate

Gas stations are equipped with a vapor recovery system so that if a tank is full, the pump will pull the extra gas you’re trying to pump into your car back into the station’s tanks. This is a safety precaution to ensure excess vapors will not escape into the environment.

GASOLINE DISTRIBUTION FACILITIES New Jersey

CONTROLLING GASOLINE EMISSIONS VAPOR RECOVERY SYSTEMS: Stage 1 : Capture vapors during transfer at marine terminals, truck loading racks, bulk terminals and at retail gas stations Stage 2: Capture vapors during fueling vehicles at retail gas stations

Vapor recovery Wikipedia

Vapor (or vapour) recovery is the process of recovering the vapors of gasoline or other fuels, so that they do not escape into the atmosphere. This is often done (or required by law ) at filling stations , in order to reduce noxious and potentially explosive fumes and pollution .

Gasoline vapour recovery system VARECO VENT/ TSF 013

Gasoline vapour recovery system VARECO VENT/ TSF 013 VARECO VENT/ TSF is an activated carbon gasoline vapour recovery system at fuel delivery points. It allows a recovery rate up to 99% of the vaporized fuel and meets with the 20. and 21.

Stage II Gasoline Vapor Recovery Regulations Ozone

This process takes the vapors normally emitted directly into the atmosphere when pumping gas and recycles them back into the fuel storage tanks, preventing them from polluting the air. The Stage II system controls the release of VOC, benzene and toxics emitted from gasoline. Vapor Recovery

VAPOUR RECOVERY Kalymnos Fuel Engineering

Designed to minimize pressure drop and maximize efficiency of the recovery of the vapours during stage 1A and 1B of the vapour recovery operations, this valve design is internationally recognized as the bench mark for poppeted vapour recovery adaptors.

Onboard refueling vapor recovery Wikipedia

Onboard refueling vapor recovery. However, an ORVR system is able to retain those emissions, delivering them to the vehicle's carbon filled canister and then to dispose of those vapors by adding them to the engine intake manifold and the stream of fuel supplying the engine, during normal operation.

Vapour Recovery System UK Petrol Diesel Petrochemicals

The prevailing method of vapour recovery globally is, and has been for decades, adsorption of the VOCs (volatile organic compounds VOC are chemicals that have high vapour pressure like Petrol, Diesel, Methanol, Crude Oil, Benzene, paints and ) onto activated carbon. Following adsorption, the activated carbon is regenerated by applying vacuum to these, the so called pressure swing adsorption

Gasoline Vapor Recovery 24 Hour Notification System

Gasoline Vapor Recovery 24 Hour Notification System. Reporting Guidlines. If any portion of a specific test fails, always mark the testing failed. If any portion of a specific test passes but, the remaining tests are not conducted, mark the testing as cancelled.

Enhanced Vapor Recovery (EVR) For Gasoline Dispensing

• The following comments apply only to the Phase II vapor recovery system of gasoline dispensing facilities (GDF). • They do not apply to diesel dispensing facilities. • They only apply to underground gasoline storage tanks (UST) at this time. • At some point in the future there will also be EVR requirements for above ground storage tanks (AST).

Vapour Recovery Systems Flotech Performance Systems

Vapour Recovery Systems You are here: Home / Vapour Recovery / Vapour Recovery Systems At Flotech we have over 30 years experience in Vapour Recovery Units (VRU), we offer units suitable for recovery of VOCs (Volatile Organic Compounds) in truck, rail, marine and tank breathing applications.

Gasoline Vapor Recovery Department of Environmental

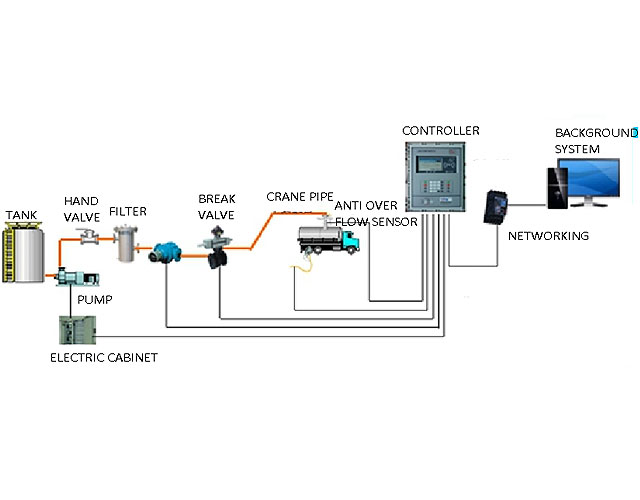

Stage I vapor recovery refers to the capture of gasoline vapors generated when a tank truck delivers gasoline to a storage tank at a gasoline dispensing facility (GDF). As the storage tank is filled, the vapors are transferred to the tank truck, which then carries the vapors to the gasoline distribution terminal.

Stage I Vapor Recovery Petroleum Equipment Institute

Stage I Vapor Recovery. In a typical Stage I system, the gasoline transport driver connects two hoses between the delivery truck and the storage tank to which the delivery is being made. Gasoline from the truck flows through one hose into the storage tank. Displaced vapors, pushed out of the storage tank by the rising liquid,

Vapour Recovery for Petrol Filling Stations

A vapour recovery system helps to collect petrol vapour released during unloading and refueling back to the petrol tanker and underground storage tank, respectively. [Click to slide show] How do I know which stations have refueling vapour recovery system? If a station has installed this vapour recovery system which passes the required tests, it

Frequently Asked Questions about Vapor Recovery Units (VRUs)

A VRU, or vapor recovery unit, is a compression system used to collect and compress low volume gas streams for injection into the suction of a larger compressor, a meter run, a local site fuel gas system or directly into a gas gathering line. Mechanical VRUs consist of a driver motor or engine that supplies the power to the compressor.

Fuel vapor recovery system Ford Motor Company

A fuel vapor recovery system for an automotive vehicle includes a fuel tank, a first vapor recovery canister, a second vapor recovery canister, and a bypass flow metering element. The first canister has an inlet communicating directly with the fuel tank and an outlet.

Installing Vapor Recovery Units on Storage Tanks

Installing Vapor Recovery Units on Storage Tanks (Cont’d) changing fluid levels and agitation of tank contents associated with the circulation of fresh oil through the storage tanks. Standing losses occur with daily and seasonal temperature changes. The volume of gas vapor

Vapor Recovery Executive Orders California Air Resources

For Gasoline Dispensing Facilities (GDFs) with no Phase II Vapor Recovery System: Executive Order NVR 1 D (Low Permeation Hoses and Enhanced Conventional (ECO) Nozzles) EVR system determination letters are issued by the State Water Resources Control Board to assure EVR systems will not conflict with underground storage tank statutory requirements.