vapour recovery system tankers

Vapor Transfer Vents to transfer displaced vapors

As a key component in the vapor recovery system, the vapor transfer vent (VTV), fitted to the Manhole Cover, provides the means to transfer displaced vapors to and from the tanker. Supplied air operated and sequenced with the emergency valve, our Vapor Transfer Vents ensure vapors are transferred safely during the loading and unloading process.

Vapor Control John Zink Hamworthy Combustion

Vapor Control Solutions. Superior, Field Proven Performance. Our VCUs can achieve volatile organic compound (VOC) destruction efficiencies greater than 99 percent, resulting in hydrocarbon emissions less than 10 milligrams per liter of product transferred. In addition, our VCUs satisfy all the applicable requirements of 40 CFR .

Vapor recovery Wikipedia

Vapor recovery is also used in the chemical process industry to remove and recover vapors from storage tanks. The vapors are usually either environmentally hazardous, or valuable to be recovered. The process consists of a closed venting system from the storage tank ullage space to a vapor recovery unit (VRU) which will recover the vapors for return to the process or destroy them, usually

Tank Vapor Recovery Safety in Design LBCG

Vapor Recovery System Key Considerations VRU System Should be Plant Specific One Size does not “fit All” Prioritize Recommendations based on Tank Permit Requirements Location of Flare or Export Gas System Toxic Gas Release Mitigation Ultrafab/Sulfatreat Resources, Cost and Schedule Provide Training Pertaining to the Proper Design and Operation

Cargo Tank

Cargo Tank Vapor Recovery Program aims to reduce volatile organic compounds (VOC) emitted by gasoline cargo tanks. Through cargo tank certification, CARB verifies and certifies the tank’s vapor recovery systems adequately captures emissions released during gasoline transport and delivery.

Tank Trailer Vapor System Olsta Co

The vapor system on a tank trailer allows the vapor to be removed from the trailer when you’re loading product, or added to the trailer as your unloading. Vapor system parts include vapor recovery adaptors, sequential vapor vents, vapor hoods, and other parts to help keep your trailer safe when loading or unloading product.

Installing Vapor Recovery Units on Storage Tanks

Installing Vapor Recovery Units on Storage Tanks (Cont’d) changing fluid levels and agitation of tank contents associated with the circulation of fresh oil through the storage tanks. Standing losses occur with daily and seasonal temperature changes. The volume of

STANDARDS FOR VAPOUR EMISSION CONTROL SYSTEMS

3 SHORESIDE TERMINALS 3.1 General 3.1.1 A vapour emission control system design and installation should eliminate potential tanker overfill hazards, tanker overpressure and vacuum hazards, and sources of ignition to the maximum practical extent, in accordance with good design and engineering practice.

Stage II Vapor Collection System Enforcement Discretion

Stage II Vapor Collection System Enforcement Discretion Directive. Therefore, the Department of Environmental Conservation is revising 6 NYCRR Part 230 to, among other things, reduce volatile organic compound (VOC) emissions from gasoline dispensing

State of Oregon: AQ Programs Gasoline Vapor Recovery Program

DEQ also requires tankers to connect vapor recovery equipment when delivering gasoline at dispensing facilities. Gasoline dispensing facilities Gas stations and other dispensing facilities are subject to National Emission Standards for Hazardous Air Pollutants rules put into law by the U.S. EPA and adopted by DEQ (OAR 340 Division 232, 242, and 244).

Vapor Recovery Unit VRU Package Unimac LP

VRUs (Vapor Recovery Units) are relatively simple systems that can capture about 95 percent of the Btu rich vapors for sale or for use onsite as fuel. Recovered vapors contain natural gas liquids, that have a Btu content that is higher than that of pipeline quality natural gas (between 950 and 1,100 Btu per standard cubic foot [scf]).

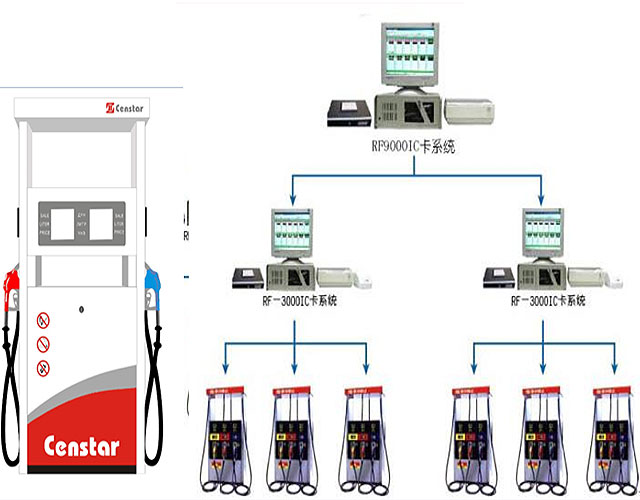

Vapor Recovery Systems 101 Censtar

Federal law mandates gasoline vapors are recovered at Gasoline Dispensing Facilities. This video explains why.

VAPOR RETURN SYSTEM CHEMICAL TANKERS CAPT AJIT

VAPOR RETURN SYSTEM CHEMICAL TANKERS CAPT AJIT VADAKAYIL VRS. USCG regulations wrt vapour recovery systems and then issue a certificate in accordance with 33 CFR —signed by master. Vapor return calculations: Find out the VD of the chemical. Say for EDC it is . from your VCS manual use the graph drawn for pressure drop in mm Aq

Fuel Vapour Recovery Adapter Alpeco Ltd

This valve is specifically designed for vapour recovery applications. VAP400AIC: 4” vapour adaptor fitted with a dust cap, an interlock for interlocking brakes and a vapour dump valve when a vapour hose is connected: PKL400 VAP: A 4” parking lug is designed to allow the VAP400C to be parked up without opening the valve: VAP300C: Self sealing vapour coupler designed for 3″ vapour hoses.

VAPOR RECOVERY SYSTEMS Symex Technologies

Vapor Recovery System, thus preventing pollution while recovering the valuable products. Our vapor recovery process consists of two adsorber vessels for continuous operation, containing adsorbents (activated carbon) which collect the offensive compounds from the vapor stream flowing to atmosphere. The offensive vapor mixture flows upwards

Stage I and Stage II Gasoline Vapor Recovery Systems

Gasoline vapor recovery systems are categorized under two stages. Stage I gasoline vapor recovery systems capture vapors expelled from underground storage tanks at gas stations when being refilled by tank trucks. Stage II systems capture gasoline vapors that would otherwise be vented during individual vehicle refueling at gas stations.

Oil Tank Vapors PetroGas Systems

The Model BA Vapor Recovery System is mounted on a 4' x 8' skid. The processing tower is connected to the storage tank vent system. The unit is mounted on a skid, completely factory assembled, tested prior to shipment, and comes with all required equipment, including instrumentation, piping,

Stage II Gasoline Vapor Recovery Regulations Ozone

Stage II Gasoline Vapor Recovery Regulations. This process takes the vapors normally emitted directly into the atmosphere when pumping gas and recycles them back into the fuel storage tanks, preventing them from polluting the air. The Stage II system controls

Stage II Vapor Recovery Tank Integrity Services, Inc.

What is Vapor Recovery Vapor recovery is a general term describing methods for preventing the emission of volatile organic compounds (VOC) into the atmosphere. It is a process used during product delivery and fueling operations at vehicle fueling sites as a means of improving air quality.

Vapor Recovery California Air Resources Board

The California Air Resources Board’s (CARB) Vapor Recovery Program controls vapor emissions from gasoline marketing operations (gasoline dispensing facilities or service stations, tanker trucks (cargo tanks), bulk plants, and terminals), where gasoline vapor is a precursor to the formation of ozone and contains benzene, a constituent of gasoline vapor that has been identified as a toxic air contaminant.