cost for testing automatic tank gauging system

TLS 350 Automatic Tank Gauge Veeder Root

TLS 350 Automatic Tank Gauging System A legacy of reliability With over 20 years of global experience as the most installed automatic tank gauge in the industry, the TLS 350 Automatic Tank Gauge provides users with a highly flexible design for meeting compliance and fuel management needs.

Automatic Tank Gauging (ATG) North Dakota

What are the regulatory requirements for automatic tank gauging? • No later than Ap , all release detection equipment needs to be tested and inspected every year. • For automatic tank gauging systems, at a minimum, test the alarm, battery back up, and verify the system configuration. For probes and sensors, you must inspect for

Automatic Tank Gauging Products Veeder Root

Veeder Root provides highly customizable automatic tank gauge systems that provide compliance and fuel management solutions for petroleum site owners and operators around the world. Automatic Tank Gauging Products Veeder Root

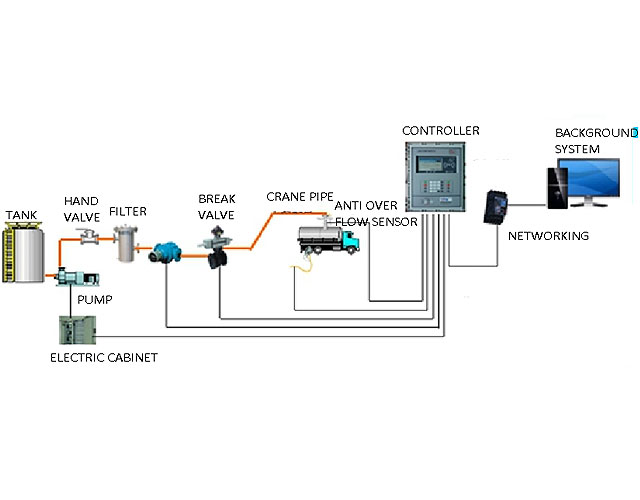

Automatic Tank Gauging Systems and Underground Storage Tanks

Automatic Tank Gauging Systems and Underground Storage Tanks How They Work. The gauge is a probe the is permanently installed in the tank. The probe connects to a processor and a monitor in a nearby facility where the operator can observe readings from the probe.

Omntec Tank Monitoring and Leak Detection Systems

OMNTEC® Mfg., Inc., is an Internationally recognized manufacturer of leak detection systems and gauging products for the petroleum industry. Omntec Tank Monitoring and Leak Detection Systems Call Us: +1 (877) 814 2001

Automatic tank gauging for underground storage tanks fact

Automatic tank gauging for underground storage tanks . Performing a monthly leak test using a properly installed and maintained automatic tank gauge (ATG) system, This fact sheet explains the requirements for automatic tank gauging for underground storage tanks.

About Rosemount Tank Gauging System Emerson US

The Rosemount Tank Gauging System supports IEC 62591 (WirelessHart ® protocol) for cost efficient automation of your tank farm. There is no need for long distance field wiring, installation costs can be reduced up to 70 percent, and the wireless solution enables access to data from tanks previously out of

Straight Talk On Tanks University of Connecticut

Manual Tank Gauging (see pages 20 21) Manual tank gauging can be used only for tanks of 2,000 gallons or less capacity. This method requires keeping the tank undisturbed for at least 36 hours each week, during which the contents of the tank are measured twice at the beginning and twice at the end of the test period. At the end of each

Release Detection for Underground Storage Tanks (USTs

Tanks 1,000 gallons or less can use this method alone, but tanks from 1,001 2,000 gallons can only use manual tank gauging when it is combined with tank tightness testing. Manual tank gauging cannot be used for tanks over 2,000 gallons.

Automatic Tank Gauging Systems For Release Detection

Automatic Tank Gauging Systems For Release Detection: Reference Manual (August 2000) 7 As the owner or operator of an underground storage tank (UST) system, you should make sure your vendor or installer provides you with the information and training necessary to guarantee your release detection equipment works effectively to detect leaks.

TLS RF Automated Fuel Tank Gauge Censtar

Low maintenance costs with expected minimum battery life of two years. Continuous monitoring . Hi end ATG features available, no loss of functionality versus wired systems. In tank leak detection . TLS RF allows third party certified tank testing to or litres per hour precision, without additional cost

Automatic Tank Gauging Systems and Underground Storage Tanks

Automatic tank gauging (ATG) systems are used to monitor product levels and detect leaks in underground storage tanks. Many tank operators use ATG systems as the primary method of leak detection and inventory monitoring, as they are both highly accurate and convenient to use. Learn more about how ATGs work, and how

Electronic Line Leak Detection Censtar

Automatic and Continuous testing: 100% probability of detection 0% probability of false alarms: Line test options: Gross line leak testing: 11.4 LPH Ultimate testing: & LPH continuous Risk management: LPH on demand Base Compliance LPH on demand: Piping Diameter and length : Up to 3" fiberglass 350' max. of 2" 150' max of 3"

Automatic tank gauging for underground storage tanks

Automatic tank gauging for underground storage tanks . Performing a monthly leak test using a properly installed and maintained automatic tank gauge (ATG) system, This fact sheet explains the requirements for automatic tank gauging for underground storage tanks.

Veeder Root Automatic Tank Gauges In MA

Automatic Tank Gauges (ATGs) installed by CommTank, are designed and manufactured by Veeder Root and are in used in monitoring more than 500,000 underground storage tanks world wide. As the world's leading supplier of ATGs, Veeder Root offers a wide range of tank gauges to meet the monitoring needs of petroleum sites.

Tank Gauging System Emerson US

Tank gauging means liquid measurement in large storage tanks to determine product volume. Rosemount™ Tank Gauging System ensures accurate level, temperature, and pressure measurements for inventory control, oil movement and overfill prevention, securing efficient operations.

Tank Gauging System From Level Measurement To YouTube

This video describes how a Tank Gauging System works. The system consists of a custody transfer certified non contacting Radar Level Gauge.

Gauging Systems Inc. (GSI) Liquid Bulk Storage Tank

Gauging Systems Inc. provides: “Services based” software for Inventory Monitoring, Tank Gauging, Overfill & Rupture protection, Leak detection (Continual and tank tightness testing), and various applications for Vapor and Ambient Air Monitoring. Distribution and Pick up Systems

Tank Gauges Field Instruments FuelsManager Software

Tank gauging is the generic name given to the measurement of liquids (product) in bulk storage tanks with the aim of quantifying how much product is in the tank, “gauging the contents of a tank”. Today, the oil & gas industry uses the static measurement of the tank contents to account for product stored and product moved into and out of the

Radar Tank Level Gauge Radar Level Transmitter

8900d High Accuracy FMCW Radar Tank Level Gauge. The Motherwell Tank Gauging 8900d digital tank radar level gauge is a high accuracy radar gauge designed for use in custody transfer tank gauging applications and exceeds the requirements of UK weights and measures standards for tank

Need For Gauging Systems INDEV ACT

In these interim periods of inactivity, the automated tank gauging systems gathers data and creates a mean knowledge analysis to see whether or not or not a tank is unbroken or leaky. For amount in testing a tank system should be pack up and aloof from operations for a period of many hours, usually throughout the course of an evening

Evaluation of the Incon Automatic Tank Gauging System for

This report describes testing conducted on the Incon Automatic Tank Gauging System. The results of this evaluation apply to the following models: TS 1000; TS 1001; and TS 2001. This evaluation meets the requirements of the U.S. Environmental Protection Agency for Automatic Tank Gauging Systems for Monthly Monitoring for 0.2 gal/h leaks of

Tank Gauging Systems Products Liquid Level Systems

The Tank Gauging System measures continuously the level, volume and temperature of the contents of ballast water, fresh water, cargo, fuel oil, bilge and mud tanks. Additionally, the vessel’s draught can be measured. High and low alarms can also be set. Series 500 liquid level transmitters ensure precise tank content and draught readings.

Tank gauging Endress+Hauser

For all of these challenges, Endress+Hauser is your partner and Tankvision the inventory management system for tank gauging, to support you to overcome these challenges. Legacy and migration Upgrading of sites with an existing tank gauging architecture accumulated over the years has its

The Benefits of Installing an Automatic Tank Gauge System

Additional functionality of an automatic tank gauge system allows for measurements of any gaps existing within the connections between tanks, pipes and hose lines, as well as the monitoring of system pressurization. Modern ATG’s are sophisticated monitoring systems that can be either wired or remotely accessed via a wireless modem.

Automatic Tank Gauging and Tank Monitoring Systems

Seneca Companies offers both Veeder Root and Franklin Fueling automatic tank gauging (ATG) and monitoring systems. With today's significant costs for cleanups, these systems are invaluable for the early or immediate detection of any system problems that may result in a release to the environment.

The Art of Tank Gauging ICEWeb

Many installations use their tank gauging system for the measurements of product transfers between ship and shore and/or pipeline transmission systems. A tank gauging system is a very cost effective and accurate solution compared to flow metering systems, especially when high flow rates are present and large quantities are transferred.

How much will it cost for an oil tank leakage test? (New

There are many cases of oil tank leaks that cost many thousands of dollars to clean up so this is critical that you have the tank evaluated. For some strange reason Long Island has been successful in keeping this as a "none issue" where as all of the surrounding areas like Westchester have this as a main issue in any real estate transaction.[/SIZE]

Tank gauging & rollover monitoring system for LNG storage

tank gauging & rollover monitoring system for lnG storage tanks. Whessoe rollover predictor DCS LNG Manager successfully passed seismic testing. Integrity and operability of the gauge remain after the event, ensuring a zFully automatic LTD gauge zLeak detection and cool down temperature system

ANNUAL AUTOMATIC TANK GAUGING EQUIPMENT

ANNUAL AUTOMATIC TANK GAUGING EQUIPMENT INSPECTION This form may be utilized to document the proper operation of automatic tank gauging (ATG) equipment. Date of Inspection ATG equipment that is utilized to meet the tank or pipe leak detection requirements is required to be inspected once every 12 months.

Tank Gauging Systems Corp Global Liquid Level Monitoring

Tank Gauging Systems Corp Products & Services Level Instruments Tank Gauging Systems Corp Manufactures a High Quality Mechanical Level Gauge using non corrosive materials in giving our clients a cost effective means to monitor any tanks Safely with Reliability in Mind.

Product Information and Frequently Asked Questions (FAQ

Connects to a RS232 port (serial port) on your Automatic Tank Gauging System with an RS232 cable. Connects to a shared phone line or router with standard telephone cable or ethernet cable. Information is transmitted to a secure website where users login to retrieve fuel and compliance information.

Results of U.S. EPA Standard Evaluation Automatic Tank

"Standard Test Procedure for Evaluating Leak Detection Methods: Automatic Tank Gauging Systems." The full evaluation report also includes a form describing the method and a form summarizing the test data. Tank owners using this leak detection system should keep this form on file to provide compliance with the federal regulations.

automatic tank gauging system best automatic tank

Buy quality automatic tank gauging system products from automatic tank gauging system manufacturer, 11574 automatic tank gauging system manufacturers & automatic tank gauging system suppliers from China.

Automatic Tank Gauging Radar Level Gauge Transmitter

When you are ready to upgrade your existing tank gauging equipment, we can provide a single piece or a whole inventory management system. We understand not all applications demand the highest accuracy; this is why we have two ranges of radar, servo and automatic

Radar Tank Gauging Honeywell

Honeywell provides training courses to help participants gain in depth knowledge on how to optimally use Radar tank gauging instruments and systems. These include hands on sessions related to operation, servicing and maintenance, diagnostics and repairs, and advanced commissioning of the systems.

Underground Oil Tank Inspection ATS Environemental

EPA Certified Tank Test with Soil Analysis Comprehensive Test. 1. Combines our tank testing services with our full soil analysis service to provide actual levels of contamination around the underground tank. 2. Corrosion evaluation which predicts whether the tank is at high risk for catastrophic failure in the near future. 3.

ust regulatory compliance web California State Water

nAUTOMATIC TANK GAUGING (Cont.) nFor “FAIL” in tank tests investigate the cause of the failed test (e.g. fuel dispensing, improper wait time after delivery, delivery during in tank test, increase in water) nCheck for frequent, unexplained high water alarms (in areas of high groundwater this may indicate groundwater intrusion into the tank,

Automatic Tank Gauging System

Considering the level of effort, significant cost, and extended ROI timeline needed to swap equipment, the engineering team decided to seek out a more practical, time and cost efficient option. It was important to find a solution that would meet the necessary accuracy requirements and support current staff levels. Automatic Tank Gauging System

Automatic Gauging for Onshore Oil and Gas Small Lease

While there has been an existing standard API for automated tank gauging for custody transfer measurement, this standard was designed for large storage tanks with requirements that are not practical and are not economical for small lease tanks. The industry realized the benefits to a more automated method of measurement.

Automatic Tank Gauging Systems Omntec

Omntec Tank Monitoring and Leak Detection Systems. Call Us: +1 (877) 814 2001 . Search for: Home; About Us; Products. Automatic Tank Gauging Systems; Leak and Level Detection; Custom Pump/Valve Controls; Automatic Tank Gauging Systems. Categories: Tank Gauge Consoles

VISY X Automatic Tank Gauging System

Sensors & Systems Worldwide: VISY Stick VISY Stick LPG VISY Stick Interstitial VISY Stick Sump VISY View Touch VISY Command VISY X Automatic Tank Gauging System for the best possible fill level monitoring Timely fuel reordering Early leak detection Identification of fuel theft Reliable quality assurance for stored fuels

Gauging Systems Inc. (GSI) ICEWeb

Gauging Systems Inc. (GSI) Innovations in Liquid Level / Mass Tank Gauging 910 Industrial Blvd., Suite A Sugar Land, Texas 77478 Phone: (281) 980 3999 Fax: (281) 980 6929 E mail: [email protected] Http:// 5 API 2509B Shop Testing of Automatic Liquid Level Gauges December 1961, Reaffirmed, August 1987

Liquid Level Control Systems Pneumercator

Third party certified for 0.1 or 0.2 gallon per hour in tank leak detection in tanks with capacities of up to 75,000 gallons Available internal impact printer or outdoor printer Auto shift inventory, unsupervised deliveries, bulk sales, alarms, leak test, water removal, product ordering, and theft logging

Fuel Tank Testing in MA

If you do choose tank testing, CommTank has years of experience in both underground tank testing and aboveground tank testing in Massachusetts. Following a proven approach perfected over the years, we test tanks and lines using ultrasonic tests, non volumetric tests, pressure or vacuum tests, or soil or water tests below the tank.

43 CFR § 3174.6 Oil measurement by tank gauging

(a) The procedures for oil measurement by tank gauging must comply with the requirements outlined in this section. (b) The operator must follow the procedures identified in API 18.1 or API 18.2 (both incorporated by reference, see § 3174.3) as further specified in this paragraph to determine the quality and quantity of oil measured under field conditions at an FMP.

Float & Tape Tank Gauging Overview CrossCo

simplest form of tank gauging. A large float follows the level of the product as it moves up and connected to a tape or wire that in turn is connected to an indicator on the outside of the tank. 2500 Automatic Tank Gauge (ATG) 2520 High Pressure Automatic Tank Gauge (ATG) 6700 Liquid Level Gauge

Tank IQ: Training Guide for Class A and B UST Operators

Automatic tank gauge (ATG) Probe inside a tank that measures product and water level and can conduct in tank testing. An ATG is usually part of an electronic monitoring system. Category 1 Tank System Any tank system whose tank was installed before Decem . (PBS only) Category 2 Tank System

Automatic Tank Gauging system ATGs YouTube

Guihe Automatic tank gauges Qingdao Guihe M&C Technology Co., Ltd Email:[email protected]

Standard Test Procedures for Evaluating Leak Detection

Individual Test Log—Automatic Tank Gauging System (five pages) 5. Reporting Form for Water Sensor Evaluation Data—Automatic Tank Gauging System (four pages) Each set of forms is preceded by instructions on how the forms are to be filled out and

Automated tank gauging, high level alarms, and oil spills

automated gauging system. Engineering crews should keep detailed notes to provide oncoming engineers with information about deficiencies of the vessels engineering systems, including oil tank gauging and alarm systems. Do not assume that automated readings are always accurate. Even if the automated tank gauging and alarm systems have been

Level Sensor, Indicator & Tank Gauge for Liquid Level Control.

Tank Liquid Level Sensor and Indicator, Ultrasonic Non Contact. For Automatic Sensing of Up to NINE ( 9 ) Tanks of Any Size, Containing Any Liquids. One control enclosure provides continuous digital level and volume indication of each tank. Does not require any programming or calibration.