fuel oil density calculation for tank gauging using a density sensor

Density of fuel oils as function of temperature

Then, use the light blue line in the Fuel oils volume correction figure ([email protected] T/[email protected]°C). At 200°C the correction factor is . The volume of your fuel oil at 15°C is 100liters* = 86 liters.

How to Calculate Fuel Density It Still Runs

If the total weight of the fluid is 16 grams, the calculation would be 16 g / 16 ml. This would give you a density of 1 g/ml. Discard the fuel from the cylinder carefully and properly. You can pour the fuel back into a car tank or certified fuel container for future use.

Bunker Calculation, Formula With Example And Sample Excel

Bunker calculation having very much significance in bunkering, at times wrong calculation can lead to shortage of bunker, oil spill etc. "corrected density" ie, density of oil at the temperature of barge or terminal is pumping (T 15)) D= density at 15°C, this you will get from bunker advice form T= Temperature of the fuel oil at which

Density Measurement Sensor

Density Measurement Sensor Whether for a new or existing installation, the Density Measurement Sensor easily installs on the OPW Magnetostrictive Probe. Combining industry leading accuracy for water, product and density measurement, the SiteSentinel® family Density Measurement Sensor uses a single magnetostrictive in tank probe assembly.

Fuel Level Measurement in tanks, vessels and containers

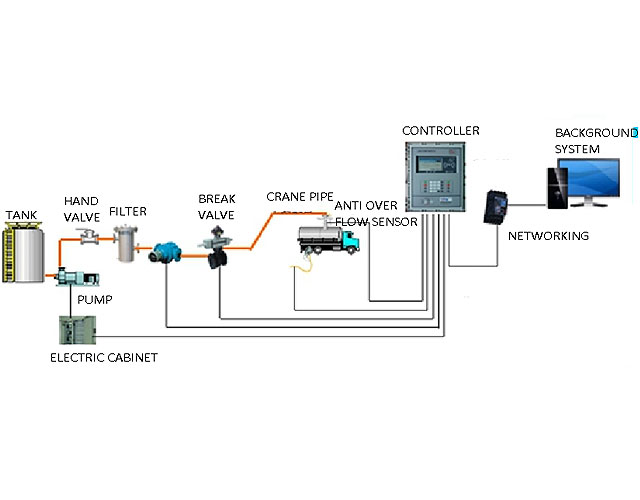

Fuel level measurement can be acheived by using fuel level sensors which work on a hydrostatic pressure principle. By installing a sensor at the base of the fuel tank or vessel or by submersing the sensor into the liquid by the top entry of teh tank or vessel the fuel sensors can associate the pressure created by the level of fuel above the device and this has a direct relationship to the level by a simple calculation.

FUEL SENTRY TANK GAUGE Model TG EL D4A

The Fuel Sentry Model TG EL D4A Tank Gauge and Leak Detection System is a remote reading, microprocessor based tank gauge, with six intrinsically safe sensor inputs that can monitor one or two tanks. The leak detection system is designed for use with double wall tanks, vaulted tanks, single wall tanks with spill basins, and double wall piping. The TG EL D4A is designed for use with all fuel oils

Hybrid Tank Measurement Systems for Mass Calculation

temperature measurement, or mass based calculation, based on density calculations using hydrostatic pressure measurement. 3.1 Tank Capacity Table (TCT) The way inventory is measured is somewhat complex. A typical tank gauging system utilises level measurement and the Tank Capacity Table (TCT) to calculate volume. Level measurement is the

Liquid Depth/Level to Hydrostatic Pressure Calculator

Fuel Density Sensor Wholesale, Density Sensor Suppliers

And whether fuel density sensor is paid samples. There are 59 fuel density sensor suppliers, mainly located in Asia. The top supplying country is China (Mainland), which supply 100% of fuel density sensor respectively. Fuel density sensor products are most popular in

Temperature vs. Fuel Density PPRuNe Forums

Temperature vs. Fuel Density. Suppose you had a 1000 cc of kerosene at 15 deg C and it weighed 800gm. If the coefficient of thermal expansion is per deg C then the change in volume down to 5 deg C and up to 25 deg C will be 1000 x x10 = 10 cc The weight of the kerosene is still 800gm, only the volume has changed.

Common Tank Gauging Technologies and How They Work Varec

Hybrid tank gauging combines an accurate level gauge, temperature sensor(s) and pressure transmitter(s). By utilizing the best of both level based and mass based systems, hybrid tank gauging obtains level, temperature compensated volumes, mass and density measurements.

Automated Calculations for Improvement of Tank Inventory

The tank gauging procedure is a time consuming task, as it must be carried out for all storage tanks within the fuel terminal. Using tank calibration table and then correcting it to a standard reference temperature (usually 60°F or 15°C) could do the determination of product volume at 30°C by using ASTM 53B and 54B conversion tables.

Tank Volume Calculator Oil Tanks

Classic uses for these two types of cylindrical tanks include using them to store fuel, oxygen or oil. Let’s look at how to calculate the volume of both of these tanks using tank capacity calculators or a cylindrical tank calculator. In the case of the horizontal cylindrical tank, you need to calculate the area of a cross section of the tank and then multiply this figure by the total length of the tank.

What is the relation between fuel oil density and temperature?

What is the relation between fuel oil density and temperature? Is used to calculate air density for the fuel injection can be found on the top of the gas tank. The fuel temperature sensor

Density Franklin Fueling Systems Americas

As the density of the fuel changes, the gap between the floats will increase or decrease in proportion to the change. The tank gauge receives this information from the probe and uses it to calculate and display the current density of the fuel. Specs. Measurement accuracy: ±1.0

1 PURPOSE 2 RESPONSIBILITIES European Commission

is the total amount of fuel in the tank after addition [t] ρ exist: is the density of the existing fuel in the tank before addition [t/m3] m exist: is the existing amount of fuel in the tank before addition [t] 4.7 Gauging Equipment In general, there are several methods of gauging fuel tanks, e.g., manual soundings, gauges

Basics of Marine Engineering: SPECIFIC FUEL OIL

Thrust SFOC is related to calculation of fuel efficiency in an engine which burns fuel to produce a thrust as an output i.e Rocket, Aeroplanes etc. Mass = Density (ρ) X m 3 It is an informative blog post on brake specific fuel oil consumption of a marine diesel engine. Ship owners would find it useful.

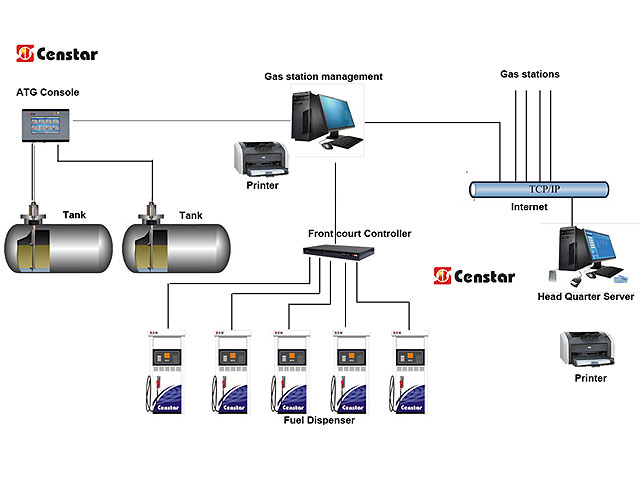

Automatic Tank Gauging Products Veeder Root

The TLS 350 Automatic Tank Gauge (ATG) has long set the standard for exceptional quality in fuel management systems. Today, the TLS 450PLUS ATG builds on that solid legacy to set a new bar for reliability and convenience.

Density & Viscosity Measurement Emerson US

With an installed base of over 175,000 densitometers and viscometers worldwide, we are at the forefront of concentration and density measurement. Our density & viscosity measurement devices offer unbeatable performance for applications in alcohol concentration, API gravity, specific gravity and more.

API Gravity Engineering ToolBox

°API = Degrees API Gravity . SG = Specific Gravity (at 60 o F) Specific gravity can be calculated from API gravity: SG = 141.5 / (°API+131.5) (2) Note! Oil with the least specific gravity has the highest API gravity. SG API Converter. SG Specific Gravity °API. Density is a temperature depedent property.

Flow, Density & Viscosity Instrumentation Rosemount

Micro Motion Viscomaster Heavy Fuel Viscosity Meter: The Heavy Fuel Viscosity Meter (HFVM) Viscomaster is a fast response, multivariable sensor designed for the measurement and control of heavy fuel oil (HFO) that supplies engines, turbines and burners in marine and power applications.

SensorsONE Measurement Instrumentation Products

Diesel Fuel Tank Level Sensors; 0.2 bar tank level pressure sensor for fuel oil up to 2m deep; 4 20mA Output Hydrostatic Level Transmitters & Sensors; G Low Cost Submersible Diesel Fuel and Water Tank Level Sensor; CIP protected dairy sensor for measuring level of milk in 6m high tank; MTM3000 10mm diameter submersible miniature pressure

Diesel Fuel Tank Level Sensors

Diesel fuel oil storage tank device for measuring diesel fuel level and converting it to an electrical signal to send to other instrumentation. G Low Cost Submersible Diesel Fuel and Water Tank Level Sensor Low cost OEM diesel fuel or water level sensor for installing inside or outside a storage tank.

Gauging Systems Inc. (GSI) Liquid Bulk Storage Tank

GSI specializes in Liquid Bulk Storage Tank Gauging & Loss Control. From Mechanical Gauges to the most advanced gauge, the MTG “Multi function Tank Gauge”. Find out more.