natural gas compressor station process flow diagram

The Interstate Natural Gas Transmission System: Scale

Pipeline quality natural gas is an odorless transparent gas, consisting primarily of methane (CH 4), with minor amounts of ethane, propane, butane, hydrogen sulfide, carbon dioxide, nitrogen, and oxygen. The first step downstream of production areas in the natural gas transmission process is separating the various liquids and gases from each other.

Process Gas Centrifugal Compressors Ingersoll Rand Air

making previously unmarketable natural gas reservoirs profitable. Ingersoll Rand has extensive experience in this process. Our custom compressors are designed to meet the varying processes and parameters involved in natural gas liquefaction. Feed Gas Compressor Compresses natural gas received at the plant to the required

Compressing costs CB&I

a station with many parallel compressor trains or a station with just one compressor train; thus allowing the investigation of using multiple trains for varying conditions. For the transmission of 100% of the design flow of gas, all the compressor stations must be operational.

Natural Gas Industry Process Flow Diagram SmartDraw

Natural Gas Industry Process Flow Diagram. Create Process Flow Diagram examples like this template called Natural Gas Industry Process Flow Diagram that you can easily edit

Process flow diagram Typical oil refinery Natural gas

The process flow diagram example "Natural gas condensate PFD" was drawn using the ConceptDraw PRO software extended with the Chemical and Process Engineering solution from the Chemical and Process Engineering area of ConceptDraw Solution Park. Read more. Process flow diagram

Compressor Stations Tennessee Gas Pipeline

attached diagram.) 1. Station Yard Piping Natural gas enters and exits the compressor station through station yard piping. Gas enters the station at the suction header. From there, gas passes through the scrubbers, which remove any solids and most liquids from the gas. Because the temperature of natural gas rises when it is compressed, high pressure gas coolers may be used to

Appendix C Process Flow Diagrams

Tail Gas + Natural Gas . Furnace Fried at 30% Full Load . To Atmosphere . Steam/Air Mixture . Effluent sent to combustion chamber (i.e. Firebox) Notes: 1. Max decoking firing time for all six furnaces is 864 hours per year @ 30% normal load (119 MMBtu/hr) 2. Decoking operations will occur a maximum of 12 events per year per furnace.

(PDF) HANDBOOK OF NATURAL GAS TRANSMISSION AND

HANDBOOK OF NATURAL GAS TRANSMISSION AND PROCESSING. 2006. Wagner Soriano. Download with Google Download with Facebook or download with email. HANDBOOK OF NATURAL GAS TRANSMISSION AND PROCESSING. Download. HANDBOOK OF NATURAL GAS TRANSMISSION AND PROCESSING.

Natural Gas Compressor Station Process Flow Diagram Buy

Natural Gas Compressor Station Process Flow Diagram , Find Complete Details about Natural Gas Compressor Station Process Flow Diagram,Natural Gas Compressor Diagram,Natural Gas Compressor Manufacturers,Natural Gas Compressor Station Process Flow Diagram from Supplier or Manufacturer Henan Yuanju Machinery Equipment Co., Ltd.

Landon Carroll R. Weston Hudkins University of Oklahoma

just over $220 worth of natural gas wasted in fuel costs per year per compressor station. Another assumption is that the pipe and compressor are running 350 days a year.

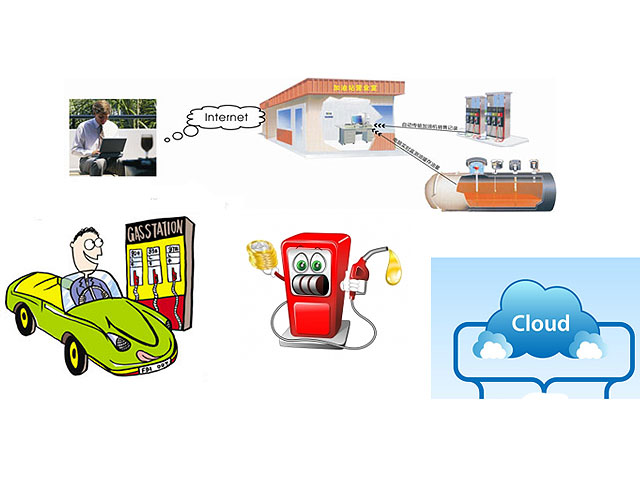

Compressed Natural Gas (CNG) Filling Stations Honeywell

Honeywell's Gas Filling Stations offer solutions including control stations for compressed natural gas (CNG), fuels and the growing biogas market. The station technology is available in two series that differ by the supply and nominated capacity.

Natural Gas Liquids Recovery.

may provide for a higher sales value than the pipeline gas by itself. Figure 1 shows a block flow diagram for a typical natural gas processing scheme, and indicates where CRYO PLUS™ is integrated within the operation. CRYO PLUS™ Benefits The optimum C 2 and C 3

Oil and Gas Pipeline Construction: Step By Step Visual Guide

Pipeline Construction: Step by Step Guide The current natural gas pipeline boom gives many homeowners a first row seat to the process of pipeline construction. The rush to move natural gas to markets places pipelines too close to homes, with construction taking place in backyards, farms, pastures, and right at the mailboxes of residents

Compressor Stations—an essential part of a natural gas

What is the purpose of a compressor station? Maintains the pressure of natural gas as it flows through a pipeline. Why are compressor stations needed? Natural gas loses pressure and may pick up contamination in the pipeline. The compressor stations increase pressure and can include technology to remove liquid and particle contamination picked up in transit. Compressor stations are located at

Natural Gas Compressor Stations on the Interstate Pipeline

more than 1,200 natural gas compressor stations to maintain the continuous flow of natural gas between supply area and consumers (Figure 1). Compressor stations are “pumping” facilities that advance the flow of natural gas. They are usually situated between 50 and 100 miles apart along the

Mallnow Natural Gas Compressor Station Climate friendly

The Mallnow natural gas compressor station Is one of WINGAS TRANSPORT’S largest compressor hubs. Transports volumes of gas that make up around a third of Germany’s natural gas requirements. Uses the waste heat of the gas turbines to drive an additional steam turbine.

Compressor station Wikipedia

Compressor station. A compressor station is a facility which helps the transportation process of natural gas from one location to another. Natural gas, while being transported through a gas pipeline, needs to be constantly pressurized at intervals of 40 to 100 miles. Siting is dependent on terrain, and the number of gas wells in the vicinity.

Gas Compressor Package YouTube

We have delivered gas compressor packages for power plants up to 200 MW (based on 2 up to 4 gas turbines). The "typical" gas compressor range of Eltacon: gas inlet between 1

Types of Gas Compressors Piping engineering

A gas compressor is a mechanical device that increases the pressure of a gas by reducing its volume. Compressors are prime movers of gas and air in process industries. They are used to increase static pressure of the gas and deliver it at specified pressure and flow rate in a process application. Use of compressed gas can be found in numerous applications.

Docket No. CP80 (DESIGN MANUAL) Exhibit Z 9.2 Stations

2.1.8 Process The process flow diagram of the station main gas piping is shown on Figure . This includes the launcher and r eceiver, liquid vapor separators (scrubbers), pipeline compress or, chillers, gas heaters and blow down dr um with flare stack. The nor mal sucti on pressure at t