procedure guide for construction of lpg filling plant and autogas station pdf

Safe use of liquefied petroleum gas (LPG) at small

Safe use of liquefied petroleum gas (LPG) at small commercial and industrial bulk installations When the risks are properly identified and managed, LPG can be safely used as a fuel source for many applications. This information is aimed primarily at users of LPG to provide information and help to ensure it is used safely. Users may wish to

ELECTRICAL INSTALLATION OF FACILITIES FOR THE STORAGE

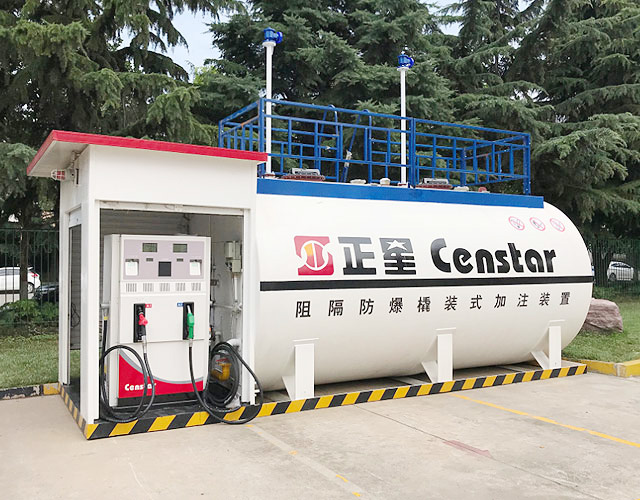

Liquefied Petroleum Gas (LPG) for use in motor vehicles, generally known as Autogas, is being encouraged in the UK as an alternative fuel because of its cleaner burning characteristics and environmental benefits. Autogas may be sold alongside other motor fuels at vehicle refuelling stations or at dedicated Autogas stations.

lpg refilling plant cost establishment in nigeria

Procedure Guide for Construction of LPG Filling Plant and Autogas gas filling plant and manufacturers' data sheet of the storage tanks with codes certified cheque made payable to "Federal Government of Nigeria . Following the unprecedented demand for LPG in Nigeria and Petroleum Gas {LPG} Storage and Distribution filling station

Lpg Filling Stations, Lpg Filling Stations Suppliers and

A wide variety of lpg filling stations options are available to you, such as free samples, paid samples. There are 4,941 lpg filling stations suppliers, mainly located in Asia. The top supplying countries are China (Mainland), Turkey, and India, which supply 99%, 1%, and 1% of lpg filling stations respectively.

PROJECT STANDARDS AND SPECIFICATIONS general

PROCEDURES (PROJECT STANDARDS AND SPECIFICATIONS ) Page 8 of 40 Rev: 01 Feb 2011 Hydrostatic Testing 1. Hydrostatic pressure testing of the Unit shall be performed to prove strength of the materials and weld integrity after completion of the construction. The tests shall be made on new or repaired equipment and piping. The initial

LP Gas Serviceman’s Manual

slow filling. • If a vapor equalizing hose is used, the air, and any moisture it contains, will be transferred from the storage tank to the transport. Additionally, if atmospheric air is properly purged from the storage tank; • the storage tank will fill faster, • appliances will perform more consistently

By Authority Of

tions for the storage and handling of liquefied petroleum gas (LPG) at marine and pipeline terminals, natural gas processing plants, refineries, petrochemical plants, and tank farms. This standard takes into consideration the specialized training and experience of operating personnel in the

Installation Guidance: CNG Refueling Stations DVRPC

Station Installation Safety Valves and Devices oStorage: A manual shutoff valve installed at the outlet of storage. oDispenser: Breakaway protection shall be provided in the event of a pull away fuel stops to flow due to separation. oDispenser: A quarter turn manual shutoff valve may be required at a

BULLETIN 500 001 LIQUEFIED GAS HANDBOOKReplaces

the physical properties of propane and butane. The specific gravities of the liquids are just over half that of water. This means a gallon of propane or butane weighs only half the weight of a gallon of water. Also, propane and butane have viscosity of about 0.1 centipoise, which make them approxi mately 10 times thinner than water.

NFPA Liquefied Petroleum Gas Code 58 Fire Safety Analysis

• Be familiar with NFPA 58 Liquefied Petroleum Gas Code 2001 Edition, and • Have a better understanding of the requirements and other regulatory provisions for preparing a Fire Safety Analysis (FSA) for the storage of propane gas (LP Gas) and • Be able to institute a written Operations & Maintenance for a bulk propane storage facility in

LP GAS SERVICE TECHNICIAN’S HANDBOOK

Purging Propane Gas Containers is the removal of water and air from the containers prior to installation and filling at a customer’s site or at the bulk plant. Water and air in a propane container will seriously contaminate and interfere with an entire propane system, resulting in improper operation of not only the system, but also the

Costs Associated With Propane Vehicle Fueling Infrastructure

procedure for filling a propane storage tank. Options include: o A fleet manager has the tank filled at a specified frequency, such as once per week. o The tank is monitored with a sensor that notifies the supplier when filling is necessary. o A fleet manager tracks the fuel use and submits tank fill requests based on fleet needs and fuel pricing.

AutogAs & fill stAtion EquipmEnt Ray Murray

AutogAs & fill stAtion EquipmEnt sy if this is the onlY type you will ever fill from this dispenser then standard 20lb fill station equipment will suffice. (prinz system for example) • Quality Tank produces a 1,000 gallon Autogas specific tank that has 3 bottom openings with side load and side gauges.

DPR

guidelines for lpg plant june 2010 department of petroleum resources 1 dpr department of petroleum resources the procedure and conditions to be fulfilled before the grant of approval and licence for the construction, modification, relocation of a liquified petroleum gas (lpg) filling plant and autogas station petroleum regulation 1967

Civil Engineering Sector Labour Management Health and

Procedure: Procedure for The Storage and Handling of Fuel on Construction Sites. All other terms as defined in the Liquid Fuels Handling Code, 2007. RESPONSIBILITIES It is the primary responsibility of the Supervisor(s) to ensure that all fuel handling, dispensing, and storage is done in a safe and proper manner in accordance with this procedure.

Petrol Filling Stations

Design, Construction, Modification and Maintenance of Petrol Filling Stations’ (the Blue Guide2). Site operators will, therefore, need to refer to the Blue Guide when following this guidance. c) the health risks associated with coming in to contact with petrol/petrol vapour. d) environmental issues such as contamination of groundwater, water

BULLETIN 500 001 LIQUEFIED GAS HANDBOOKReplaces

This means a gallon of propane or butane weighs only half the weight of a gallon of water. Also, propane and butane have viscosity of about 0.1 centipoise, which make them approxi mately 10 times thinner than water. This property makes LPG a difficult fluid to pump since a low viscosity fluid is harder to seal and prevent pump slippage.

User Information Sheet 026

The Red Guide(2) states: ‘Portable LPG Cylinders (24); Customers or untrained attendants should not be allowed to fill portable LPG cylinders from the Autogas dispenser’(3). ADR(4) states: “The filling of pressure receptacles may only be carried out by specially equipped centres, with qualified staff using appropriate procedures”. The Law

Autogas Installation step by step Digitronic Autogas

Installing an autogas system in the car has many advantages. That is why it is a solution that enjoys uninterrupted interest. The installation of LPG or CNG is a savings that in the long run will give you possibility of much cheaper travel. The cost of installation and assembly components varies in different countries, however it [ ]

Safety Report Assessment Guide: LPG

HID SAFETY REPORT ASSESSMENT GUIDE: LPG. Safety Report Assessment Guide: LPG. Introduction. The purpose of HSE’s assessment of a safety report against the criteria in the SRAM, is to come to a conclusion on whether the requirements and demonstrations in