purpose of offset filling pipes in gasoline station

61T Drop Tube OPW Retail Fueling

The OPW 61T Drop Tube is installed in the fill riser pipe to an underground storage tank. It is designed to transfer product from the fill connection point (between the delivery drop elbow and tight fill adaptor) to within 6" (or per local requirements) of the bottom of the tank.

Fuel Tank Venting and the Charcoal canister

of the tank. These tubes are in turn connected to the fill pipe of the gas tank via a 2 3way tees and the plastic tubing aforementioned earlier in this article. The venting system is there to allow air into the tank to avoid a vacuum as the car uses its gas supply and also to vent the tank when heat expands the gas vapors in the tank as well.

FRP Products Petroleum Fiberglass Piping

When a fluid is pumped through a pipe, the magnitude of the electrostatic charge generated will increase as the velocity increases. When this liquid is transferred into a smaller pipe, the liquid velocity will increase as will the static charge. When a filter is placed in the pipe, the static charge generation increases by a factor of 10 to 100.

46 CFR § Vent pipes for fuel tanks. CFR US

46 CFR Vent pipes for fuel tanks. The flame screens must consist of a single screen of corrosion resistant wire of at least 30 × 30 mesh. The flame screens or flame arresters must be of such size and design as to prevent reduction in the net cross sectional area of the vent pipe and permit cleaning or renewal of the flame screens or arrester elements.

Semi blocked gas tank / Problems with filling tank? MNSubaru

You can see the fuel filler neck as the cover was removed,it's really easy to remove. up top is 3 screws holding the filler pipe in, just follow it down below for the main filler hose that runs into the gas tank. the small lines to the right of the filler neck belongs to the air vent pipe. the rest (2 evap hoses that connect to the air vent pipe, the filler hose) are hidden from view, on top of the rear crossmember,

Hazardous Area Classification and Control of Ignition Sources

Hazardous Area Classification and Control of Ignition Sources. This Technical Measures Document refers to the classification of plant into hazardous areas, and the systematic identification and control of ignition sources. The relevant Level 2 Criteria are 5.2.1.3(29)c, (63)f, and 5.2.4.2(93)a.

Air Valve Basic Training Ohio Water Environment Association

•Pipe Breaks • Erratic operation of pumps, meters, and Sources of Air Entry in Pipelines • Dissolved Air or Gas (2% at 1 atm) •Air Valves • Pumps • Filling Empty Pipelines. Why Air Valves? Sources of Vacuums in Pipelines •Draining Pipelines •Water Hammer Microsoft PowerPoint 1115 Air Valve Basic Training

NFPA 58 Requirements for Dispensers Ray Murray

NFPA 58 Requirements for Dispensers 2001 edition 3.9 Vehicle Fuel Dispenser and Dispensing Stations. From points of transfer in LP Gas dispensing stations and at vehicle fuel dispensers 10 (b) From other points of transfer 25 Standard Pipe Connectors for Flammable and Combustible Liquids and LP Gas

Article 514 Motor Fuel Dispensing Facilities

Article 514 Motor Fuel Dispensing Facilities. By Mike Holt, for EC&M Magazine. Imagine how terrible it would be if you were putting gas in your company truck or your personal automobile, and the gas dispensing station erupted into a ball of fire.

What is a Pipe Sleeve? (with pictures)

A pipe sleeve is generally one of three things: a protective ring used to keep a pipe hole open, a ring used to fill the gap between a pipe and another surface, or a covering to create a barrier between a pipe and its surroundings. These sleeves are used during the construction of a building or pipe

Tank Filling Systems Simplex Inc.

Full with filling operations locked out at High Level. A leak detection circuit prevents filling of leaking tanks. Visual and audible level and leak alarms and continuous level indication are provided. The Simplex Automatic Fuel Port is available for use with fuel oil (Class II liquids) or gasoline (Class I liquids).

Deck Plates, Caps & Fills Go2marine

Perko Deck Fills for Pipe marked with Fuel (Gas or Diesel), Water or Unmarked. Perko deck fills complement your boat with a choice of chrome plated or plain bronze finish a range of sizes $

Why are these pipes built in a strange way? Ask MetaFilter

You'll also see this where gas comes into a house, the connection between the meter and the house will have a a couple 90s on the same axis offset a foot or more. that allows the meter to move up and down relative to the house without the pipe breaking off. The 90s acts like a hinge. posted by Mitheral at 3:05 AM on Ap

Fire & Explosion Risks in Service Stations

Service Stations Petrol Vapour Petrol gives off highly flammable vapour even at very low temperatures. Because of the flammability of petrol vapours, service stations carry a risk of fire or explosion not common to other types of retail outlets. Ignition of petrol vapours can happen if vapour comes into contact with a heat source capable of igniting it.

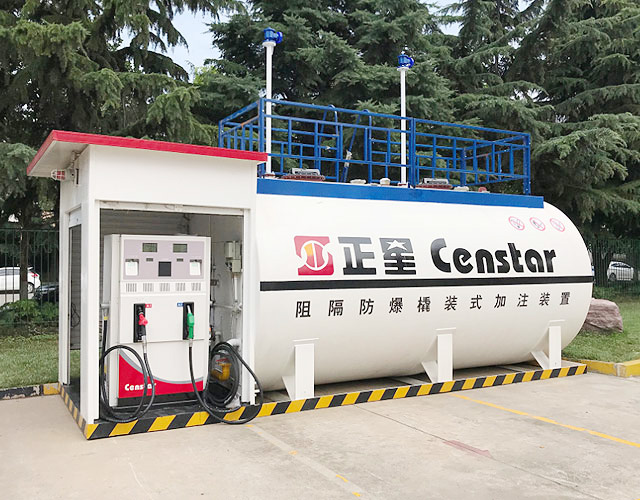

Guidelines on Decommissioning Fuel Storage Tanks

• The filling/dipping pipes should be kept securely locked. All offset fill pipes to be adequately secured against unauthorised access, vandalism or inadvertent use. A competent person as defined by the Guidance for the Design, Construction and Maintenance of petrol filling stations

Sanitary sewer system rehabilitation techniques vary

The flexibility of the resin impregnated felt tube allows it to navigated through defective sewers realigning offset joints, filling missing sewer sections, and re sealing cracked sewer pipes. The cured in place liner pipe realizes high reductions of I/I due to its ability to hold tightly to the host pipe and to form a good seal at pipe

Vertical CurvesVertical Curves Civil Engineering

Vertical Curve Computation Using the Tangent offset Eq ationTangent offset Equation • Select the grades, and hence find V’s • Th d i dfi L ih di b?The designer defines L, sight distance maybe? • Compute the station of BVC, from the station of V andL h h i fEVC ddL/2d L, then compute the station of

REFRIGERANT PIPING INTRODUCTION

The chief purpose of this discussion on refrigerant piping is to point out some of the precautions to be taken which affect each compressor discharge line should be connected to the main hot gas line in a “Y” or offset “T”, as in Figure 66F02A and Figure 66F02B, but never bull headed, as in Figure 66F02C. Increase liquid pipe

REGULATION III

212 OFFSET FILL LINE 213 ORGANIC LIQUID 214 STATIONARY STORAGE TANK 215 SUBMERGED FILL PIPE 215 SUBMERGED FILL PIPE Any discharge pipe or nozzle which meets the applicable specification as follows: service station or other operation handling gasoline

: Chapter 05. Ventilation, Drainage, and

Chapter 05. Ventilation, Drainage, and Waterproofing. From . Openings in the roof of the tunnel, with sidewalk gratings, are provided over the station platforms, and generally one about half way between each station and one at each end of the stations on the side toward the approaching train, these latter being expected to take