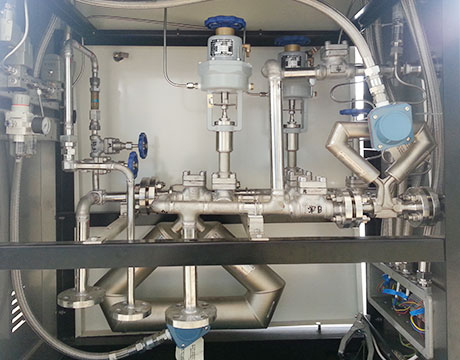

road tanker vapour recovery system

Road Tanker Safety design, equipment and the human

Road Tanker Safety design, equipment and the human factor 06/05/2019 by Tracy Mikulec Around 25% of all freight hauled in the US is transported in tanker trucks, and of that, nearly half is petroleum products (gasoline, diesel, and aviation fuel)*.

PRODUCT DATA SHEET BRENNER TANK TRAILER

» Vapor Recovery: .. (1) 3"x2" tee style hydraulic vapor recovery valve with hydraulic system of the emergency valve using : same hydraulic hand pump. Pressure gauge on curbside leg. Roadside leg has 2" SS piping down side of tank to rear of trailer ending with pressure gauge, 2"SS ball valve, 2" SS adapter and dust cap. »Cleanouts: ..

Vapor Recovery Executive Orders California Air Resources

Vapor Recovery Executive Orders. The Executive Orders are available for downloading in PDF file format. For Gasoline Dispensing Facilities (GDF) equipped with Underground Storage Tanks (UST), select from the following categories: Phase I EVR. Phase II EVR. Phase I Pre EVR. Phase II Pre EVR. Phase II Pre EVR ORVR Compatible.

Bulk Transportation of Liquid Petroleum

For example, in transferring gasoline into a road tanker, the loss often exceeds 0. and in many cases the value of the product recovered can pay for the cost of the vapor recovery system

ENGINEERING STANDARD FOR PROCESS DESIGN OF

manhole is sealed and vapors are diverted into a vapor return system. The latter may be either integral with the loading arm or a vapor manifold on the vehicle connected to all the tank compartments which would be similar to the system described in (b) below. b) Bottom loading

Road Tanker Bottom Loading Censtar

Petroleum road tanker bottom loading system designed and installed by IFC Inflow at a UK Oil Distribution depot. The loading system comprises the overfill an

TCEQ Tank Truck Loading of Crude Oil or Condensate

Note: Loading cannot occur while the control system is off line. Vapor balancing is NOT a form of control; it is only a capture technique. This form is for use by facilities subject to air quality permit requirements and may be revised periodically. Tank Truck Loading of Crude Oil or Condensate (Revised 11/13) APDG 6217v2 Page 4 of 6

Stage I and Stage II Gasoline Vapor Recovery Systems

Gasoline vapor recovery systems are categorized under two stages. Stage I gasoline vapor recovery systems capture vapors expelled from underground storage tanks at gas stations when being refilled by tank trucks. Stage II systems capture gasoline vapors that would otherwise be vented during

Electronic Terminal Systems Scully Signal

Electronic Terminal Systems. Scully systems are the number one choice worldwide for overfill prevention, grounding, and vehicle identification safety at bottom and top loading terminals. Control fills and eliminate spills of petroleum and liquid chemicals into tank trucks and rail tank cars.

Tank Truck Products Civacon

Civacon Products Designed for safeguarding people and the environment. Civacon is dedicated to designing, manufacturing and distributing world class solutions for the safe handling and transporting of petroleum products.

Top Loading Arm With Vapor Recovery System Petroleum

Top Loading Arm With Vapor Recovery System Petroleum Chemical Industry Fluid Loading Process Equipments , Find Complete Details about Top Loading Arm With Vapor Recovery System Petroleum Chemical Industry Fluid Loading Process Equipments,Top Loading Arm With Vapor Recovery System,Fluid Convey Equipments,Liquid Loading Accessories from Chemical Storage Equipment

Vapour Recovery System UK Petrol Diesel Petrochemicals

Vapour Recovery System VRU The prevailing method of vapour recovery globally is, and has been for decades, adsorption of the VOCs (volatile organic compounds VOC are chemicals that have high vapour pressure like Petrol, Diesel, Methanol, Crude Oil, Benzene, paints

Vehicle fuel tank vapor recovery system (Patent)

A fuel filler system is described, comprising: a fuel tank; an open ended fuel filler tube connected to the tank and having a vapor vent leading to a canister, the open end of the filler tube closed by a removable threaded filler cap: and internal threads cooperating with the filler cap threads for

DRIVER CHECKLIST FOR LOADING AND UNLOADING

USING THE API COLOR SYMBOL SYSTEM TO MARK EQUIPMENT AND VEHICLES FOR PRODUCT IDENTIFICATION AT GASOLINE DISPENSING FACILITIES AND DISTRIBUTION TERMINALS. (3rd Edition July 2006) NC Fire Code requires each fill pipe for motor fuel at a service station must have a label or must be painted a particular color to represent the product in the tank.

AP 42 Section 5.2: Transportation And Marketing Of

These vapors are a composite of (1) vapors formed in the empty tank by evaporation of residual product from previous loads, (2) vapors transferred to the tank in vapor balance systems as product is being unloaded, and (3) vapors generated in the tank as the new product is being loaded.

Vapour recovery at service stations

Vapour recovery control equipment aims to capture petrol vapours before they enter the atmosphere. They are designed in two stages VR1 and VR2. VR1 captures displaced vapours from storage tanks when a tanker delivers petrol to a service station, while VR2 captures displaced vapours at the bowser while a motorist refuels.

Vapor Recovery Systems at Best Price in India

Vapour Recovery Systems Carbon Tech VRUTM find application in Storage Tank Farms & Truck, Rail & Marine loading facilities for Petroleum & Petrochemicals. The recovery process is based on adsorption on activated carbon .The activated carbon is then regenerated by Vacuum.

Changes in the Vapor Recovery Program

when we witness the vapor recovery testing. This benefits both the TMB and the owner/ operator in several ways: • All of the tank top manhole covers and dispenser covers are typically open during annual testing. This reduces the amount of time to complete an inspection and

For Tankers, 'Vapor Recovery' Works Two Ways Trailer

“Checking air flow,” he explained. A blower pushed air into the tanker as its load flowed out “to keep the tank from getting crushed” by atmospheric pressure. “When you load, you pull the air out to keep it from exploding.” That part’s called “vapor recovery,” he added. Oh, sure.

Fixing 1970s Evaporation Control Systems Allpar

Fixing 1970s and 1980s Fuel Evaporation Control Systems. The open fuel systems used through the late 1960s freely vented gasoline vapors, which reacted with sunlight to form toxic smog. The fuel system had two external vents: one at the fuel tank (sometimes through the cap), and one at the carburetor float bowl.