safety procedure for fuel dispense

Standard Operating Procedures Dispensing Rx Advisor

Standard Operating Procedures Dispensing . Receiving Prescriptions Purpose To ensure a high standard of customer service and the safe, secure, and efficient handling of prescriptions received at the dispensary. Scope . The procedure covers the receipt of NHS and private prescriptions presented at the dispensary. Procedure / Process . 1

Kerosene Safety Signs from

Kerosene Signs and Labels. Wherever Kerosene is stored or used, safety is always a concern. Fortunately, posting signs about Kerosene reminds everyone to be cautious and follow established safety procedures. Kerosene signs and labels from can help prevent costly injuries and downtime. They're available in a variety of

Civil Engineering Sector Labour Management Health and

Procedure: Procedure for the Handling of Fuel on Construction Sites All other terms as defined in the LFHC, Section 1.4. 4.0 RESPONSIBILITIES 4.1 It is the primary responsibility of the Supervisor(s) to see to it that all fuel handling and dispensing is done in a safe and proper manner in accordance with this procedure.

YOUR PETROLEUM STORAGE TANK FACILITY INSPECTION

YOUR PETROLEUM STORAGE TANK FACILITY INSPECTION GUIDE HOW WELL DO YOU KNOW YOUR PETROLEUM STORAGE AND DISTRIBUTION SYSTEM? This publication can be made available in large print, tape cassette or braille by request.

Safe Work Procedure Fuel Storage & Handling

Safe Work Procedure Fuel Storage & Handling The information contained in this document is provided for use by Fuelco Pty Ltd as a guide where a safe work procedure for the safe storage and handling of fuel does not exist. Please check local requirements and OH&S regulations before using or implementing. Sequence Hazards Process Precautions

Safety and environmental standards for fuel storage sites

Safety and environmental standards for fuel storage sites Final report 7 The recent Texas City and Buncefield incidents have moved industry and regulators beyond the pure science and engineering responses to develop ways to prevent a recurrence. They have caused us to also critically examine the leadership issues associated with delivering what

Petrol Stations Health and Safety Authority

Fuel and oil spillages on the forecourt can present a slipping hazard Supplies of industrial salt mixed with fine gravel should be kept and spread on the forecourt during icy conditions and also used promptly to absorb and clean up any fuel or oil spill.

Refuelling safety Housing Public Works

materials (e.g. the fuel and the metal fuel filler neck). When the static electricity discharges, it produces sparks which can ignite the fuel vapours. The fuel dispensing pumps found at service stations and the fuel filler necks of motor vehicles are earthed to minimize and control the static electricity produced during normal vehicle refuelling.

Occupational Health & Safety (OHS) in Petrol Stations

Procedures to be followed in the event of spillage, and particularly the spillage of flammable liquid on clothing. Risks when draining fuel tanks, particularly over inspection pits. Precautions for hot work on vehicle fuel tanks. Safety of electrical equipment used in

Service stations

Service stations store and handle large amounts of hazardous chemicals and present unique hazards, due to the flammability of their products. In order to manage the risk of dispensing fuel safely service station operators must manage and maintain sites according to the work health and safety legislation and relevant standards. Safety duties

F&AM, Engineering Safety & Health Tech Tips

before dispensing fuel. Ground and/or bond all containers before opening and dispensing fuel. Physically touch the outside of containers, grounds, and bond wires to bleed excess charges off your body. Touch the outside of metal and plastic containers with the fill nozzle before opening and dispensing fuel. Use labeled safety containers with anti

Aircraft Systems: Aircraft Fueling and Defueling Procedures

Safety procedures to be followed when perform fueling and defueling. Sequence in defueling an aircraft’s fuel tanks avoids structural damage. Follow the manufacturer’s procedure for defueling the aircraft. What to do with the fuel coming out of a tank depends on a few factors.

API Staying Safe at the Pump

Staying Safe at the Pump. Static electricity related incidents at retail gasoline outlets are extremely unusual, but the potential for them to happen appears to be the highest during cool or cold and dry climate conditions. In rare circumstances, these static related incidents have resulted in a brief flash fire occurring at the fill point.

LIQUID FUEL DISPENSER & PUMP SERVICE MANUAL

LIQUID FUEL DISPENSER & PUMP SERVICE MANUAL Liquid Fuel Dispenser & Pump Service Manual Version 1.0.1 explain all servicing procedures, warnings, and safety precautions as clearly and completely as possible. However, due to the range of operating Compac liquid fuel dispensers are designed to meter petrol and diesel under the

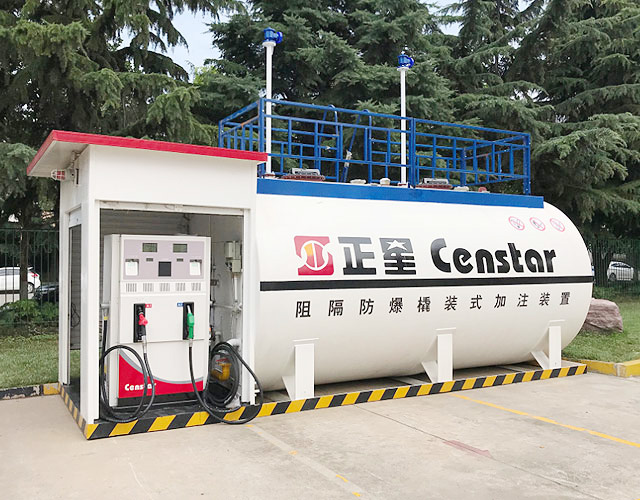

Technical Training & Documentation Censtar

North America Technical Training Gilbarco provides a wide range of expert resources to ensure outstanding field support for you. We have an extensive offering of classes, certified trainers, and video and traditional documentation.

MSU Standard Operating Procedures Vehicle and

MSU Standard Operating Procedures Vehicle and Equipment Fueling Introduction and Purpose Vehicle and equipment fueling procedures and practices are designed to minimize pollution of surface or ground waters. Understanding the procedures for delivering fuel into vehicles, mobile fuel tanks, and storage tanks is critical for this purpose. Safety is

WAYNE OVATION INSTALLATION & OPERATION MANUAL

View and Download Wayne Ovation installation & operation manual online. Ovation Dispenser pdf manual download. Also for: Ovation series, Ovation r13,

Test Procedures for Inspecting Fuel Dispensers

Test Procedures for Inspecting Fuel Dispensers (90 liters/min or less) 1. Standards 2. Device Use 3. Visual Exam 4. Performance 5. Sealing Physical Standards Physical Standards Certified Within Prescribed Period (R56) Test Measures must be certified every 1 year Provers with valves must be certified every 4 years (some 2 years)

Civil Engineering Sector Labour Management Health and

Civil Engineering Sector Labour Management Health and Safety Committee July 2008 The dispensing of fuel from a highway tank or mobile refuelling tank to a motor vehicle with hoisting equipment in accordance with normal safety procedures.

Electrical Safety for Motor Fuel Dispensing Facilities

Meeting the NEC disconnect requirements at motor fuel dispensing facilities provides necessary safety for personnel and station equipment during maintenance and service activities. The current requirements in NEC and emphasize that the system low voltage circuits are included and must be disconnected as well.