specifications for gas gathering station

3.2 Natural Gas fired Reciprocating Engines

Most natural gas fired reciprocating engines are used in the natural gas industry at pipeline compressor and storage stations and at gas processing plants. These engines are used to provide mechanical shaft power for compressors and pumps. At pipeline compressor stations, engines are used to help move natural gas from station to station.

Specifications And Requirements For Gas Installations

The purpose of this book is to present information, specifications, and requirements pertaining to the delivery of natural gas by Central Hudson Gas & Electric Corporation (the Company). Adherence to the specifications and requirements set forth herein will protect the interests of the Customer and the

By Authority Of

onshore gas gathering pipelines for the sole purpose of pro viding users with a practical guide for determining the appli cation of the definition of gas gathering in the federal Gas Pipeline Safety Standards, 49 CFR Part 192, and state pro grams implementing these standards. The definition of "gas gathering" reflects the varied nature

Fact Sheet Gathering Centers, Flow Stations BP

(known as “ gathering centers ” on the western side of the field GC 1, GC 2, GC 3,and “ flow stations ” on the eastern side Flow 1, Flow 2, Flow 3) is to separate raw crude oil, water and gas produced from the wells into the three main components. The crude must meet certain pipeline specifications before being shipped to Pump Station 1

» Processing Natural Gas

The extracted natural gas is transported to these processing plants through a network of gathering pipelines, which are small diameter, low pressure pipes. A complex gathering system can consist of thousands of miles of pipes, interconnecting the processing plant to upwards of 100 wells in the area.

The Interstate Natural Gas Transmission System: Scale

The natural gas pipeline network in the U.S. consists of gathering pipelines, interstate natural gas transmission pipelines, intrastate natural gas transmission pipelines, natural gas Typical pipeline quality gas specification is a moisture content of 7 lbs of water or less per 1 Natural gas compressor stations. Source: EIA web site.

Oil and Gas Production Handbook: Midstream facilities

Many upstream facilities include the gathering system in the processing plant. However, for distributed gas production systems with many (often small) producers, there is little processing at each location and gas production from thousands of wells over an area instead feed into a distributed gathering system.

Håvard Devold Oil and gas production handbook An

Oil and gas production handbook An introduction to oil and gas production, transport, refining and petrochemical industry Håvard Devold

Oil and gas production handbook ed1x3a5 comp NTNU

In a distributed production system this would be called the gathering system. The remainder of the figure is the actual process, often called the Gas Oil Separation Plant (GOSP). While there are oil or gas only installations, more often the well stream will consist of a full range of hydrocarbons from gas

A 34 Piping Design and Test Requirements

The design of all new gas facilities and any subsequent additions or alterations to existing facilities shall meet the expected future class location and, as a minimum, the planned future MAOP requirements of the pipeline. Attachments B and C of this gas standard contain specifications for commercially available pipe commonly used at PG&E.

Natural Gas Gathering Gas Compressor Applications

Ariel offers application specific components, engineered to ensure the performance, safety, and reliability of your natural gas gathering operation. This includes safety options and corrosion resistant materials for those gathering applications where the gas contains acidic or toxic components, such as hydrogen sulfide and carbon dioxide.

Oil and Gas Upstream and Pipeline Flowserve

mainline and booster pipeline stations. Flowserve pioneered secondary recovery through high pressure water injection and first applied submersible motor pumps in crude oil and LPG storage caverns. Oil and gas well drilling continues at a high level of activity worldwide but with ever increasing difficulties of location, landscape and depth.

How Does the Natural Gas Delivery System Work? American

Gas flowing from higher to lower pressure is the fundamental principle of the natural gas delivery system. The amount of pressure in a pipeline is measured in pounds per square inch. From the well, the natural gas goes into "gathering" lines, which are like branches on a tree, getting larger as they get closer to the central collection point.

VOL II Final Technical Tender 20 9 08 Oil India

Gathering, Custody Transfer and Metering Delivery Terminal (Central Gas Gathering Station and Off take Point; CGGS & OTP) at Madhuban, Duliajan in Upper Assam, India. The Field Gathering Stations in particular, would also be utilized to test gas wells, generate adequate data / information required for proper reservoir management. The fluid

Directive 017: Measurement Requirements for Oil and Gas

Directive 017: Measurement Requirements for Oil and Gas Operations (December2018) i. Release date: Decem Effective date: Decem (except where otherwise stated) Replaces previous edition issued Novem . Measurement Requirements for Oil andGas Operations .

gathering system Schlumberger Oilfield Glossary

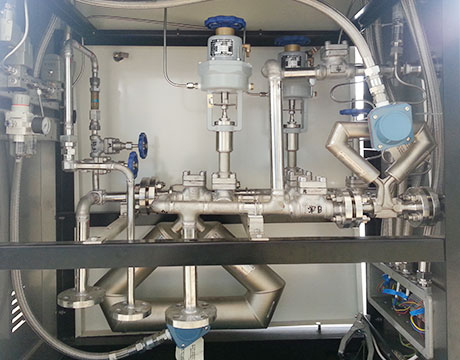

The flowline network and process facilities that transport and control the flow of oil or gas from the wells to a main storage facility, processing plant or shipping point. A gathering system includes pumps, headers, separators, emulsion treaters, tanks, regulators, compressors, dehydrators, valves and associated equipment. There are two types of gathering systems, radial and trunk line.

Process Design Basics for Stations Facility

Process flow diagram 1. Purpose. The purpose of this article is to establish the design basis electrical system Front End Engineering Design (FEED) and data design or standards uses in the gathering stations facility will be built. Electrical system design refers to the process flow diagram and utility flow diagrams, existing data of flow diagram contain of equipments that’s requires