bottom loading vapour recovery system

Loading Arm Systems and Components SafeRack

No. 1 provider of OPW or Emco Wheaton loading arms for truck or railcar loading, complete loading platform systems. Overfill and Vapor Recovery Truck and Railcar Liquid Level Sensors and Vapor Recovery Solutions; Top and bottom pump and loading arms FRT gangway transloader.

vapour recovery Flotech Performance Systems

Bottom Loading with Vapour Recovery Suitable for bottom loading of road tankers with API Coupler Connections. The arms can be designed to connect to side of the tanker and also cross over to suit the configuration of the tanker connections.

Vapor Recovery from Truck Loading Chemical plant design

Question: What is the typical method/strategy used for vapor recovery of vapors displaced during truck loading? The commodity is light crude oil. The trucks will be bottom loaded. The connection for the vapor line is on the bottom also, if that matters. Thanks in advance!!

Tank Truck Bottom Loading Advantages Assentech

Bottom loading is a method of filling tank trucks by pumping Chemical, Petrochemical or Petroleum products into cargo tanks through a system of valves and fittings mounted under a truck. While the traditional method of loading (Top Loading) is through the open manhole covers on the top of

Railcar loading systems Arid Technologies

VRU (Vapour recovery unit), Control system a.o. Valves and product system, piping Shell Deutschland Oil / Ludwigshafen Deutschland, 2007 Engineering and delivery of equipment for a 2 track On Spot loading system for railcar loading of Benzine, Diesel and Heating oil with two filling tube systems.

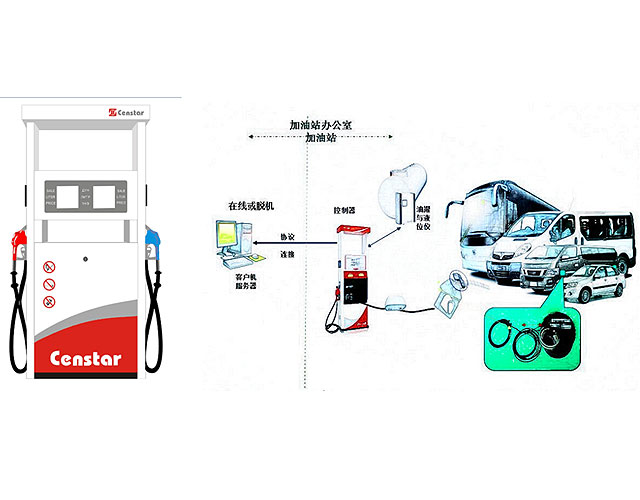

Road Tanker Bottom Loading Censtar

Petroleum road tanker bottom loading system designed and installed by IFC Inflow at a UK Oil Distribution depot. The loading system comprises the overfill and ground monitor, high accuracy Acuflow

Application for Bulk Loading Facility Vapor Recovery

APPLICATION FOR BULK LOADING FACILITY VAPOR RECOVERY SYSTEM CERTIFICATION . Monitoring and Laboratory Division Vapor Recovery In Use Section Bottom Loading Top Loading is used at the loading rack 6. Product hose connector (dry break) for connecting cargo tank to product line is a Date of Vapor Recovery System Installation and date

Code of practice for petroleum road tanker vapour

recovery unit, where the petrol vapour is returned to the liquid state before being pumped back to storage. When unloading at a filling station the process is reversed.

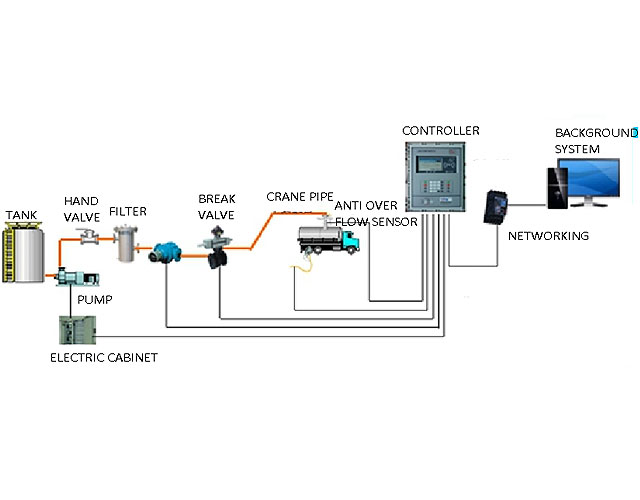

Bottom Loading And Vapor Recovery System (BLVR)

EMCO Wheaton BLVR Bottom Loading & Vapor Recovery Systems allow safer, faster and cleaner tanker truck loading and unloading. BLVR systems provide vapor return, vapor reduction, cost reduction and closed filling. EMCO Wheaton's BLVR System complies with internationally standards such as API RP1004 and ADR.

Load Rack Vapor Recovery System SAS Tech Solution

Load Rack Vapor Recovery System Modern Bottom or Top Loading systems incorporate vapor recovery systems that control and collect vapors displaced form an empty compartment as it is filled and prevent them from escaping into the atmosphere and causing ozone damage.

Bottom Loading Arms Emco Wheaton

Bottom loading offers benefits which cannot be achieved with top loading designs. As it takes place on the ground, it is inherently safer for the operator. It also allows for simultaneous loading of several tank compartments, increasing speed and efficiency of loading. Bottom loading is easily adaptable to vapor recovery systems.

Vapor Recovery Loading Arms OPW Engineered Systems

Vapor Recovery Loading Arms OPW Engineered Systems offers the world’s most complete line of Top Loading Vapor Recovery Solutions. With the variations in transports that exist today, it’s important to partner with a company that has the experience, the technologies and the breadth of

Petroleum Bottom Loading Arm Options Woodfield Systems

Petroleum Bottom Loading Arm Options. Drop Hose: An explosion proof electrical control system to continually monitor static charge accumulation in the vehicle. to advise the position of the loading arm Vapour Recovery: A Separate Loading Arm: To carry the vapour recovery hose and adapter;

Retail Site Vapour Recovery Soliflo

Bottom Loading Arms Retail Site Vapour Recovery VR Refiner System Is installed into the fuel station vent system to enable all displaced petrol vapours, normally lost to site, to be processed, converted to fuel and returned to the storage tank for immediate re sale Can be installed on a site without environmental controls in place or

Bottom Loading Vapour Recovery Arms Loadtec

LOADTEC VAPOUR RECOVERY LOADING ARMS are designed to capture the vapours displaced from the road tanker or rail tanker, during filling operations. The most common method for collection of vapours during filling, is via a cone shaped plug that closes the open manhole and diverts the vapours back to the loading rack. This could be via a hose, piggybacked onto the liquid arm or via a separate

Industrial Flow Systems Integrated Systems

Bottom Loading and Vapor Recovery System (BLVR) The advantages of bottom loading are well proven, with most oil companies having standardized on the practice internationally. The benefits of a Vapor Recovery System are that it is safer, faster, cleaner and provides the ability for vapor return, vapor reduction, cost reduction, and closed filling.

Bottom Loading & Vapor Recovery Systems (BLVR)

Wholesale Bottom Loading & Vapor Recovery Systems (BLVR) from verified Dealer, Distributor, supplier, Ali Yaqoob Trading Co. L.L.C on .

Transportation Fuel Delivery Parker Hannifin

Bottom Loading Vapor Recovery systems allow fuel tankers to be filled more quickly and the harmful vapors are recovered and are not allowed into the atmosphere, meeting and exceeding environmental standards. B.L.V.R. Systems reduce the occurance of single point leakage during the initial installation and the subsequent service life of tanker vehicles.

Bottom Loading & Vapor Recovery Systems (BLVR)

The advantages of bottom loading are well proven, with most oil companies having standardized on the practice internationally. The benefits of a Vapor Recovery System are that it is safer, faster, cleaner and provides the ability for vapor return, vapor reduction, cost reduction, and closed filling.

Vapor Recovery Service Novaflex

Vapor Recovery Service. Hoses are ideal for use with petroleum and petrochemical vapor recovery systems in ship to shore, bottom loading and tank truck applications. This hose is lightweight and flexible. Manufactured to meet specification CF33 154. Rated for full vacuum.