fuel dispenser iec test report

UL 6 Household and Similar Electrical

1 Scope. This clause of Part 1 is replaced by the following. This International Standard specifies safety requirements for electrically operated commercial refrigerating appliances that have an incorporated compressor or that are supplied in two units for assembly as a single appliance in accordance with the manufacturer’s instructions (split system).

ELECTRICAL SAFETY TEST EQUIPMENT Google Sites

The existence of electromagnetic immunity requirements is essential to assure safety of equipment and systems. The immunity test levels specified in this standard (IEC 60601 test levels) represent the range found in the general medical use environment.

IEC Standard Home

IEC 6 :2018 applies to electrically operated water valves for use in, on or in association with equipment for household and similar use, including heating, air conditioning and similar applications. The equipment can use electricity, gas, oil, solid fuel, solar thermal energy, etc., or a combination thereof.

DFS

VenU helps businesses improve performance by identifying specific business needs, goals and objectives; focusing on best practices; and designing training venues that maximize knowledge. VenU delivers complete blended learning solutions combining world class e Learning courseware, and highly effective classroom training. Pre built and customizable e Learning courses Custom courseware

NITP 5.1 National Instrument Test Procedures for Fuel

NITP 5.1 describes the test procedures for the verification and in service inspection of fuel dispensers (other than LPG dispensers) to assess whether they measure to within the maximum permissible errors (MPEs) specified in the National Trade Measurement Regulations 2009 (Cth) and that they comply with the Certificate of Approval.

Secondary Containment and Under Dispenser Containment

Under Dispenser Containment (UDC) Beginning on Ap owners and operators must install under dispenser containment for all new dispenser systems. A dispenser system is considered new when both the dispenser and the equipment needed to connect the dispenser to the UST system are installed at an UST facility.

Monthly Walkthrough & Inspection Checklist

Monthly Walkthrough & Inspection Checklist (continued) Inspection point Jan Feb Mar Apr May Jun Jul Aug Sep Oct Nov Dec Inspection date Dispenser hoses, nozzles, breakaways Inspect for loose fittings, deterioration, obvious signs of leakage or improper functioning. Dispensers and dispenser sumps Open each dispenser and inspect visible piping,

Australian/New Zealand Standard SAI Global

Australian/New Zealand Standard Fuel dispensing equipment for explosive atmospheres 1 SCOPE AND GENERAL 1.1 Scope This Standard specifies requirements for design, construction and testing of fuel dispensing equipment. The tests specified herein are intended as type tests to prove a particular design for compliance with this Standard.

ISO 19880 1, Hydrogen Fueling Station and Vehicle

ISO 19880 1, Hydrogen Fueling Station and Vehicle Interface Safety Technical Report (ICHS # 116) 3 P a g e 3. Hydrogen dispensing 3.1 Hydrogen Station Dispensing description Hydrogen fuel cell electric vehicles (FCEVs) can be fueled using dispensers that

Standard Operating Procedures Manual SOPs

Standard Operating Procedures Manual SOPs This SOP’s will detail the steps taken to provide fuel for IEC vehicles from the fuel dispensing site at the Stock IEC Building. (The fuel dispensing location or stock should be separated from fuel use, as identified on the daily fuel disbursal report, at minimum on a monthly basis.

STRATEGIC OUTCOMES PRACTICE TECHNICAL ADVISORY

automotive fuel dispensing facilities should not exceed 18 ft. (5.5 m). Where hose length at marine motor fuel dispensing facilities exceeds 18 ft. (5.5 m), secure the hose to protect it from damage. Underwriters Laboratories UL 330, Standard for Safety for Hose Assemblies for Dispensing Flammable Liquids, covers hose and

Fuel Dispensers CEYPETCO

The Fuel Dispensing Pumps Model/s offered shall hold a pattern approval as per the requirements of International Organization of Legal Metrology (O1ML) standard R 118 :2000 “Testing Procedures and Test Report format for Pattern Examination of fuel dispensers for Motor Vehicles and constituent Element” & OIML R 117 :1995 “Measuring System

TEST REPORT Emerson

TEST REPORT Report Number: 100739395MIN 005 Project Number: G100739395 The observations and test results in this report are relevant only to the sample tested. This report by itself does not imply that the material, product, or service is or has ever IEC 6 Voltage Fluctuations Emissions N/A IEC 6 Electrostatic Discharge

Dispensing Equipment Testing With Mid Level Ethanol

Dispensing Equipment Testing With Mid Level Ethanol/Gasoline Test Fluid . Summary Report . November 2010 . Kenneth Boyce, Principal Engineer Manager Energy In the case of fuel dispensing equipment, materials that were selected—based on a Dispensing Equipment Testing With Mid Level Ethanol/Gasoline

Working Group Report 2016 APLMF

Working Group Report 2016 Training Coordination (OIML R 49 and ISO/IEC 17025). The training would also include information outlined the test procedures and the reference standards of measurement used to test a fuel dispenser to ensure it is operating correctly and delivering fuel within the maximum permissible . 7 . APLMF

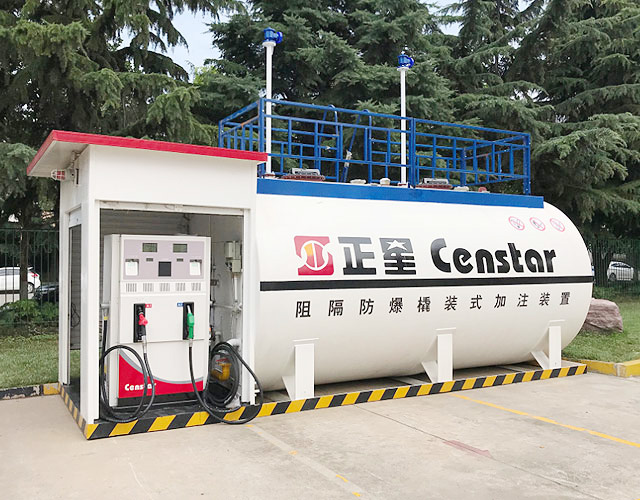

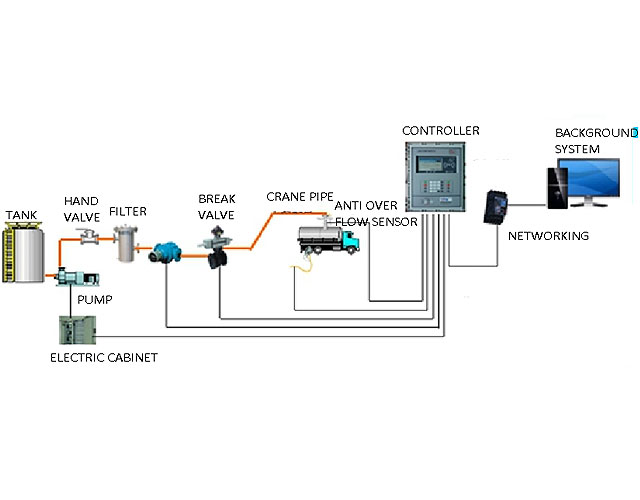

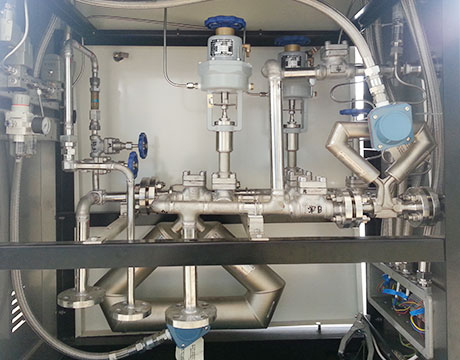

Fuel Dispenser Censtar

Sign in to report inappropriate content. Fuel dispenser fraud 2 Tokheim, Schlumberger, Adast, Topaz, 5 Ways Every Fuel Retailer Can Boost Profitability Duration:

Organisation Internationale de Métrologie Légale

The standardized test report format for pattern evaluation of fuel dispensers for mo tor vehicles is given in Annex A. 2 Test equipment and test conditions Ambient temperature: except when otherwise specified, the ambient temperature shall not vary by more than 10 °C during the test. Ambient temperature shall be meas

Verification of fuel dispensing pumps WMA

Determine whether the dispenser has passed or failed. 6.0 Accuracy Test The following series of test procedures are for determination of fuel dispenser accuracy. After wetting standard capacity measure, record the internal temperature (t r). Measure and record the temperature of the fuel delivered by dispensing pump at β

For Service Technicians Weights and Measures NH

The Division of Weights and Measures licenses, pursuant to RSA 438, service technicians authorized to test, calibrate and certify commercial devices including a variety of scales, analytical balances (e.g. a precision scale), retail motor fuel meters (e.g. gas pumps), vehicle tank meters, taxi meters, etc.

Recommended Practices for Inspection and Maintenance of

Recommended Practices for Inspection and Maintenance of Motor Fuel Dispensing Equipment PEI/RP500 11