natural gas compressor station layout

BASICS OF GAS COMPRESSOR STATIONS Metropolitan

Compressor stations are designed with continuous monitoring devices along with emergency shutdown systems capable of isolating the station and safely venting the gas very quickly in the unlikely event of an emergency. Since natural gas is lighter than air, natural gas

The basics of a compressor station The McIlvaine Company

Station Natural Gas Scrubber. As gas enters the compressor station from the pipeline, it passes through a natural gas scrubber vessel. This vessel is designed to remove free liquids, dirt or other particulates from the gas stream before it enters the compressors.

Compressor Station Design Gannett Fleming

Compressor Station Design. The stations compress the natural gas entering the facility to a specified pressure, allowing the gas to continue flowing through the pipeline to its intended destination. Another function of a compressor station is to separate and filter out liquids, dirt, and other impurities by use of scrubbers, strainers,

Gas Compressor Stations

Provide suitable gas shut off valves safely detached in both the suction and discharge lines of the station to permit safe isolation of the station from pipe line gas feed. Separate the valves and remote control stations from station buildings by at least 250 ft (76 m). Clearly label the valves and remote control stations.

Natural Gas Compressor Station And Reducing Noise Pollution

Natural Gas Compressor Station Design Simply blocking sound is no longer a sufficient mitigation option for companies. The need to eliminate noise near the source is vital to staying compliant with local and federal regulations.

49 CFR § Compressor stations: Design and

49 CFR Compressor stations: Design and construction. Each fence around a compressor station must have at least two gates located so as to provide a convenient opportunity for escape to a place of safety, or have other facilities affording a similarly convenient exit from the area. Each gate located within 200 feet (61 meters)

Considerations for Centrifugal Compressor Piping Layout

This article is intended to serve as a guide in the development of equipment layout and piping layout for centrifugal compressors and their associated equipment, with the goal of producing safe, operable, economical and maintainable installations.

Compressor Stations Engineering Entech Engineering, Inc.

Compressor Stations stations; designed to optimize flow. Natural gas compression is a critical component of any natural gas network. Whether your application is upstream at the well pad, midstream at your process facility, a prime mover in your transmission system, or a fuel gas booster for your power plant, compression is what moves your product.

Compressor Stations: What They Do, How They Work, and Why

Though natural gas is considered “dry” as it passes through the pipeline, water and other hydrocarbons may condense out of the gas as it travels. Thus compressor stations will also remove these impurities from the gas so that they can be disposed of or sold as desired.

Natural Gas Compressor Station

We were selected by UGI to fast track full permitting and design services for a 5,600 hp compressor facility in Susquehanna County, Pennsylvania. Due to higher than projected production of natural gas from prolific Marcellus Shale wells serving a Fortune 100 firm’s local manufacturing facility, compression is required to move 120/MMCF of gas per day outbound to retail markets.

Future Compressor Station Technologies and Applications

Integrals are still a workhorse for the natural gas compression industry. • Units are either 2 or 4 cycle and are typically supercharged. Horsepower ranges 600 17,000 bhp. • Manufacturers have included Cooper Bessemer, Dresser Rand, Ingersoll Rand, Worthington and Clark.

Design RLD Natural Gas Compressors

Unlike gasoline or diesel stations, compressed natural gas stations are not "one size fits all". Building a CNG station for a retail application or a fleet requires calculating the right combination of pressure and storage needed for the time period as well as the types of vehicles being fueled.

Factors in Compressor Station Design Gas Machinery

This two and a half day workshop is designed to give engineers and design professionals practical knowledge on how to design a new compressor station or evaluate the design of an existing compressor station. This course is intended for engineers

Natural Gas Compressor Stations Explained Hanging H

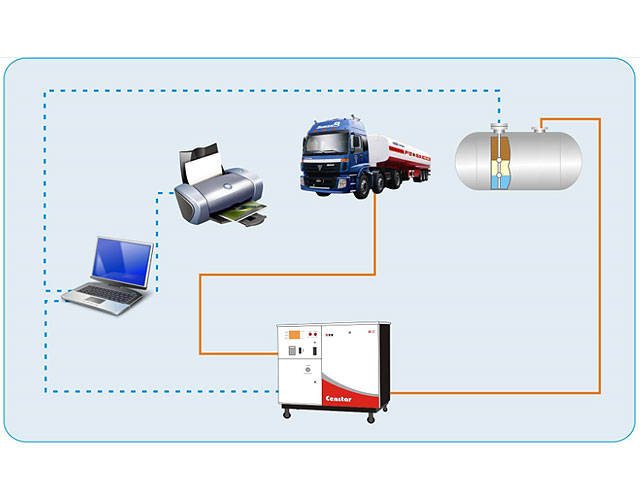

There are basically three stages for a natural gas compressor station: scrubbing, compressing, and cooling. The natural gas compressor station layout is fairly straightforward, as the gas compressor stations process is a continuous flow process. Here is a natural gas compressor station process flow diagram, courtesy of Spectra Energy. This diagram explains the process flow.

Compressor station Wikipedia

A compressor station is a facility which helps the transportation process of natural gas from one location to another. Natural gas, while being transported through a gas pipeline, needs to be constantly pressurized at intervals of 40 to 100 miles. Siting is dependent on terrain, and the number of gas wells in the vicinity. Frequent elevation changes and a greater number of gas wells will require more

Agenda Factors in Compressor Station Design Gas

Rules of Thumb for Costs of Compressor; Station & Pipeline Facilities; Compressor Station Specifics; Contents of 1 Cubic Foot of Natural Gas; Gas Terminology, Definitions, Conversions and TOPO; Compressor Station Layout. Factors to Consider; Storm Water Considerations

Natural Gas Compressor Station Design EARTHRES

The operating capacity of our client’s natural gas compressor station has doubled. Utilization of methanol was significantly reduced and potentially eliminated, reducing operating costs over $1 million annually while reducing site exhaust emission.

Compressor Stations—an essential part of a natural gas

Compressor Stations—an essential part of a natural gas pipeline What is the purpose of a compressor station? Maintains the pressure of natural gas as it flows through a pipeline. Why are compressor stations needed? Natural gas loses pressure and may pick up contamination in the pipeline. The compressor stations increase pressure and can

Natural Gas Compressor Station Two

The station is a ‘Mid Stream’ station where Natural Gas is stored until required by market demand. In addition to the Natural Gas compressor system, the nitrogen system is the main circulation driver in a closed loop refrigeration process, a modified Carnot Cycle. This nitrogen compressor is a flooded screw design that has a power rating of

CNG Micro Design Inc.

Compressed Natural Gas. Micro Design, Inc. has been a leader in the CNG industry since 1991 with over 300 CNG stations deployed worldwide. We are a certified distributor of GE Gemini compressors, it’s spare parts, as well as Bauer and Sauer compressors.