principle of operation of fuel dispensing pump

Installation and Modification of Underground Storage Tanks

Installation and Modification of Aboveground Equipment Components of Fuel Dispensing Operations. PURPOSE To facilitate the design, installation, and plan review of aboveground equipment components of vehicle fuel dispensing and to ensure that their installation complies with all applicable standards.

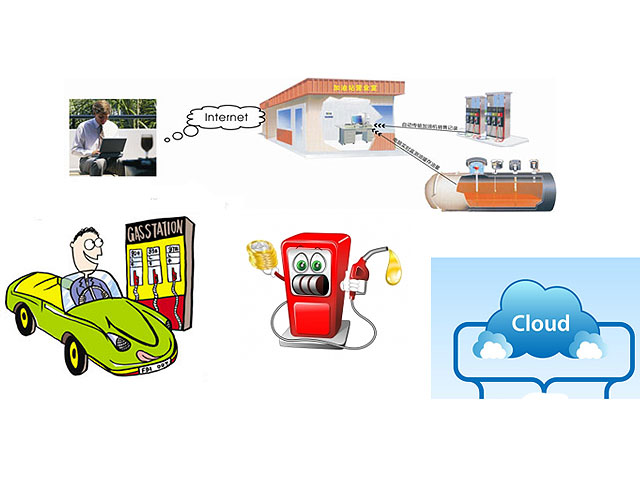

Fuel Monitoring and Electronics control of Dispenser for

(pump to dispenser) + T (dispenser to gun) = + 0.2589435 = For both the customers and dealers, the amount of fuel is compensated with the effect of temperature in fuel storage tank. Fuel dispensing control unit is controlled by temperature compensation. In order to

92 F Echo Flashcards Quizlet

92 F Echo. STUDY. PLAY. TPU. Tank Pump Unit. M controls fuel flow from the pump outlet to the inlet side of the F/S N water drain valve. Which 5k tanker has the automatic water drain valve? M969A1. Fuel dispensing flow rates for unfiltered fuel? Engine RPM 2200 2400 Pump GPM 44 88.

The fuel injector for a diesel engine how it works

Fuel oil injection system for a diesel engine The needle valve will open when the fuel pressure acting on the needle valve tapered face exerts a sufficient force to overcome the spring compression. The fuel then flows into a lower chamber and is forced out through a series of tiny holes.

Troubleshooting fuel pump problems Learn about the

This is necessary to ensure smooth running and efficient operation of the engine. The component which fulfills this purpose is known as the fuel pump. The purpose of the fuel pump is to convey the fuel reaching from its fuel tank into the individual cylinders, under the requisite high pressure in order to ensure good atomisation and good combustion. Troubleshooting fuel pump problems is an important

Section III. PRINCIPLES OF OPERATION TM 10 4930 239 12P_18

The FSSP comprises a number of separate major components to store and dispense fuel. The principles of operation of each of these major components and how they work within the system are defined in the following paragraphs. (Refer to Figure 1 3.) a. Fuel System. The FSSP is used to store and dispense fuel to using units in the field.

Fuel Dispensing Pumps Fuel Storage Systems LTD Fuel

Fuel Dispenser Range. The range of Alpha and C Series fuel dispensing pumps we offer have there frames and panels constructed from stainless steel, offering full protection from there environment which provides a long lasting life in the harshest of conditions. We offer various options with fuel transfer pump flow rates up to 180 LPM,

Verification of Fuel Dispensing Pumps Legal Metrology

A fuel dispensing system contains several sets of components to perform a number of interrelated functions. Some components maintain hydraulic continuity; regulate the direction of flow and fluid pressure. Others put the pressure on the fuel to move it through the system.

Fuel Dispensing Technology SlideShare

the rate of delivery, prevent over filling and siphoning, and assures that the components that register the volume and price are reset to zero at beginning of each delivery. o Components of the Fuel Dispensing System The types of retail motor fuel dispensing systems include the following: Self contained systems; Remote pump (or dispenser) systems; and Mechanical and electronic systems.

Standard Operating Procedures for Water Quality

Inspect the fueling equipment for leaks or spills; report leaks in hoses or tanks to supervisor immediately. Clean up fuel spills promptly with DRY methods using an absorbent material, like kitty litter or the absorbent rags in the spill kits; spills are not ‘cleaned up’ until absorbent is disposed of properly.

Fuel Dispensing Troubleshooting Husky

This is how fuel can get into all the hoses on a dispenser side. If enough fuel gets built up in the vapor line, it may be drained. The easiest method for draining the vapor line is by authorizing the dispenser, turning on the pump, point the nozzle down and lift the lever slightly but do not flow fuel. This method will allow the fuel to drain out.

Fuel Dispenser Wholesale, Mechanical Parts & Fabrication

About 26% of these are pumps, 24% are other service equipment, and 5% are rubber hoses. A wide variety of fuel dispenser options are available to you, such as free samples, paid samples. There are 19,106 fuel dispenser suppliers, mainly located in Asia.

Fuel Pressure Control Valve (FPCV) Autoditex

Fig. 1 shows how the fuel pressure control valve looks like. Fig. 1. Principle of operation of the fuel pressure control valve. The pressure control valve uses a PWM electrical signal to regulate fuel pressure in the fuel rail. A closed loop feedback circuit exists between the rail pressure sensor and the fuel pump

Fuel Injection Pump Working Principle How To Test aDiesel

Fuel injection pump working principle introduction The fuel injection pump is an important part of the diesel engine. The crankshaft gear of the engine drives the camshaft to rotate to complete the fuel injection function.

The Flow Meter HowStuffWorks

As the gasoline travels upward into the dispenser, it passes through a flow control valve that regulates the gasoline's flow speed. It does this via a plastic diaphragm that gets squeezed more and more tightly into the pipe as the flow of gas increases, always leaving just enough room for the proper amount of

Verification of Fuel Dispensing Pumps Legal Metrology

Verification of Fuel Dispensing Pumps Part IV of Eighth Schedule, The Legal Metrology (General) Rules, 2011 Specific provision: Part 2 Rule 5(1) A dispensing pump is a measuring instrument used in conjunction with a storage tank for effecting delivery of liquid products by specified volume.

How A Fuel Injector Works? Petrol vs Diesel Injector

Basically, the purpose of a fuel injector is to spray the fuel in atomized or mist form so that it burns completely & uniformly. Fuel Injection Pump (FIP) supplies pressurized diesel fuel thru’ high pressure lines to the inlet port on each injector. However, the conventional or first generation injectors open with hydro mechanical pressure.

Injection pumps principle of operation Turbo Tec

Compressed fuel in supply pumps is directed to the piston, whose movement is transmitted to the basket with rollers by means of a tang. Fuel pressure is controlled by means of a solenoid valve, which controls the flow of initially compressed fuel.

C Series Retail & Commercial Fuel Pumps & Dispensers

spillage of fuel and prevent greater damage to the Pump & Dispenser and to the environment. However, damage to the pump enclosure, hoses etc. cannot be completely prevented in some cases when a vehicle is driven away the hose still connected.

Gerotor Pumps Pump School

How Gerotor Pumps Work. 1. Liquid enters the suction port between the rotor (gray gear) and idler (orange gear) teeth. 2. Liquid travels through the pump between the teeth of the "gear within a gear" principle. The close tolerance between the gears acts as a