proteus automatic tank gauging and leak detection system

Automatic Tank Gauging Systems For Release Detection

Leak Detection Systems Automatic Tank Gauging Systems For Release Detection: Reference Manual (August 2000) 4 VENDOR CONSOLE MODEL (and probe as evaluated) PAGE NUMBER Alert Technologies, Inc. Alert Model 2000 In Tank Mass Measurement Probe System 9 Andover Controls Corp. Andover Infinity/Continuum, Versions CX9900, CX9400,

Automatic Tank Gauging Omntec Proteus Serteces, Inc.

PROTEUS Mini Me TM First of all is a color graphic display providing Automatic Tank Gauge (ATG) users the freedom to gain access to current tank gauging, leak detection and alarm status from ATG consoles. Seems like the automatic Tank Gauges monitor storage vessels for level, temperature, volume and potential leaks.

Automatic Tank Gauging Systems for Release Detection

EPA revised the UST regulation in July 2015. (EPA 510 B 00 009). August 2000. This manual can help state and EPA inspectors of underground storage tanks (USTs) evaluate how well UST owners and operators are using their automatic tank gauging (ATG) systems to comply with release detection

Omntec Tank Monitoring and Leak Detection Systems

A brighter future in tank gauging and leak detection has arrived with the PROTEUS Series. Featuring advanced technology, versatility, scalability, and enhanced features like our 7 inch color touch screen. The PROTEUS Series can simultaneously monitor product levels, water levels, temperature, leaks, and much more. The flexibility of PROTEUS

Multi Tank Gauge and Leak Detection System Preferred

The Model TG EL D5 Multi Tank Gauge and Leak Detection System is a comprehensive system that can simultaneously monitor product levels and leaks. The Model TG EL D5 combines digital monitoring and control technology with Preferred’s line of tank gauging and monitoring equipment.

CONTINUOUS IN TANK LEAK DETECTION METHOD

CONTINUOUS IN TANK LEAK DETECTION METHOD (Continuous Automatic Tank Gauging) Certification: Leak rate of 0.2 gph with PD = 100% and PFA = 0%. System reports a leak rate and a "pass" or "fail" result. Evaluated using both single and manifolded tank systems with probes in each tank.

TankLogix Benefits Tank Monitoring

Leak Detection. The Tank Warden System has built in leak detection capabilities to email or text the tank owner/operator when a leak is detected. The email or text message alerts lets the tank owner know that the tank was either drained by an unauthorized person, or there is a leak in the tank.

Underground Storage Tank Leak Detection Requirements The

The greatest potential threat from a leaking underground storage tank (UST) is contamination of groundwater, the source of drinking water for nearly half of all Americans. Effective leak detection systems can help protect you from the high costs of cleaning up extensive leaks and responding to third party liability claims.

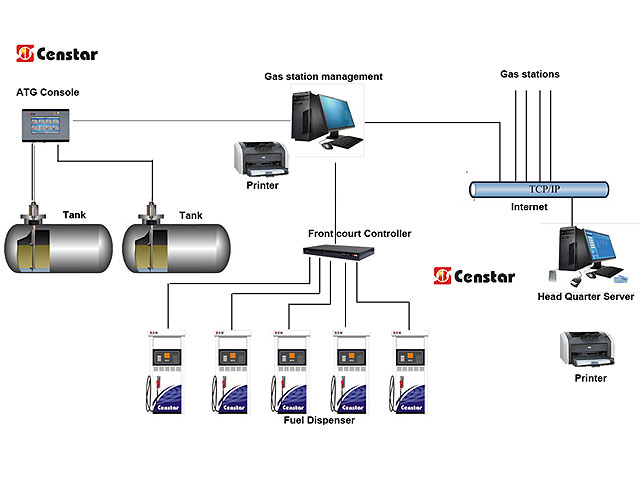

Automatic Tank Gauging and Tank Monitoring Systems

Seneca Companies offers both Veeder Root and Franklin Fueling automatic tank gauging (ATG) and monitoring systems. With today's significant costs for cleanups, these systems are invaluable for the early or immediate detection of any system problems that may result in a release to the environment.

For Underground Storage Tanks US EPA

gauging systems can serve as acceptable monthly tank leak detection methods by themselves.) Whatever form of gauge you choose to use, you must follow the SIR vendor’s instructions carefully to gather useful data. For instance, many providers of SIR services require that the tank measurements are made to the nearest 1/8 inch.

Tank Level Sensors

A brighter future in tank gauging and leak detection has arrived with the PROTEUS Series. Featuring advanced technology, versatility, scalability, and enhanced features like our 7‐inch color touch screen. The PROTEUS K Series can simultaneously monitor product levels, water levels, temperature, leaks, and much more in up to eight tanks.

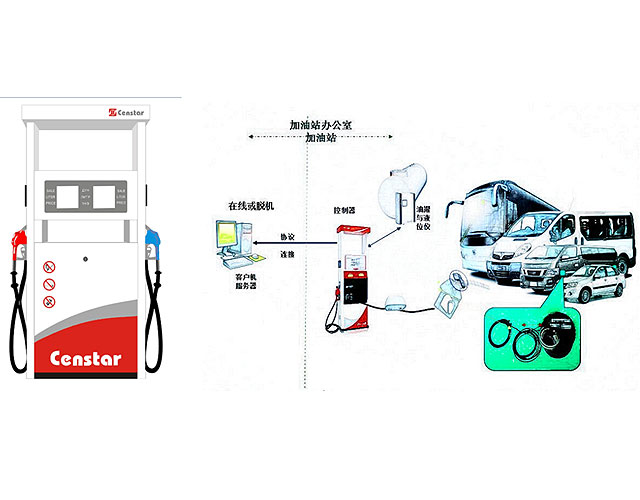

PROTEUS Mini Me Censtar

PROTEUS Mini Me is a color graphic display providing Automatic Tank Gauge (ATG) users the freedom to gain access to current tank gauging, leak detection

Proteus OEL8000IIIX Fuel Management Systems Robust

ThePROTEUSOEL8000IIIX is a comprehensive yet robust automatic tank gauging and leak detection system that simultaneously monitors product levels, water levels, temperature, and leaks in up to 16 tanks.ThePROTEUSOEL8000IIIX accepts up to 64 of OMNTEC’s Bright Eye (BX Series) sensors for distinguishing hydrocarbons from water or for simply detecting the presence of a liquid.

Electronic Line Leak Detection Censtar

Automatic Tank Gauging; Electronic Line Leak Detection; Electronic Line Leak Detection Censtar. Description. Solves your mechanical Leak testing Problems Intelligent electronic systems virtually eliminate "False Alarms" Self diagnostic system eliminates the required functional testing for mechanical leak detectors.

Automatic Tank Gauging Leak Detection Liquid

Automatic and accurate reconciliation to the sales volumes. Delivery detection with confirmation of volume, date and time. Leak detection. Remote level recording to an accuracy of 1 mm. Automatic calibration of the tank levels. Early water detection with local and remote alerts. Remote re order and minimum level alerts.

TECHNOLOGY TYPE: AUTOMATIC TANK GAUGING (ATG)

ethanol. The water sensor, tested according to "EPA's Standard Test Procedures for Evaluating Leak Detection Methods: Automatic Tank Gauging Syst ems," did not detect water in the test vessel containing either intermediate (E15) or high (E85) ethanol blends if the water was suspended in the product or the water did not reach the bottom of the tank.

Release Detection for Underground Storage Tanks (USTs

Release Detection for Underground Storage Tanks (USTs) manual tank gauging meets the federal leak detection requirements for USTs with a capacity of 1,000 gallons or less for the life of the tank. Some automatic tank gauging systems are capable of meeting the regulatory requirements for tank tightness testing and can be considered as an

Gauging Systems Inc. (GSI) Liquid Bulk Storage Tank

Gauging Systems Inc. provides: “Services based” software for Inventory Monitoring, Tank Gauging, Overfill & Rupture protection, Leak detection (Continual and tank tightness testing), and various applications for Vapor and Ambient Air Monitoring. Distribution and Pick up Systems

ICC Test Flashcards Quizlet

The space or volume above the level of motor vehicle fuel in a tank or tank system. when an automatic tank gauge is utilized for single walled tank leak detection, it shall test the tank at least monthly after product delivery or when the tank is filled within ____ percent of the highest operating level during the previous month

Proteus TANK Generator Online by reszilema Issuu

proteus tank monitoring system, proteus tank, proteus tank fit, proteus tank monitor, proteus tankanzeige, aspire proteus tank, thomas the tank engine proteus, aspire proteus replacement tank