risk management fuel dispenser

Petrol Fuel Station safety and risk assessment framework

Petrol Fuel Station safety and risk assessment framework. Other factors related to process failure also exist but requires less attention. 1203 hazard contributing factors further divided into 8 main categories. These are housekeeping (55), transportation hazard (255), slips trips and falls (215), carelessness (244), fire (17), electrical fault (97),

Commercial and Retail Fuel McPherson Oil Company

Never run out of fuel with our dedicated fleet of delivery trucks. Get fuel anytime you want it with our 24/7 never ending delivery. Get more fuel faster and cheaper with our specialized transport. Never overpay for your order because we use tank wagons for smaller deliveries. You always have options of Diesel or Unleaded Gasoline delivery.

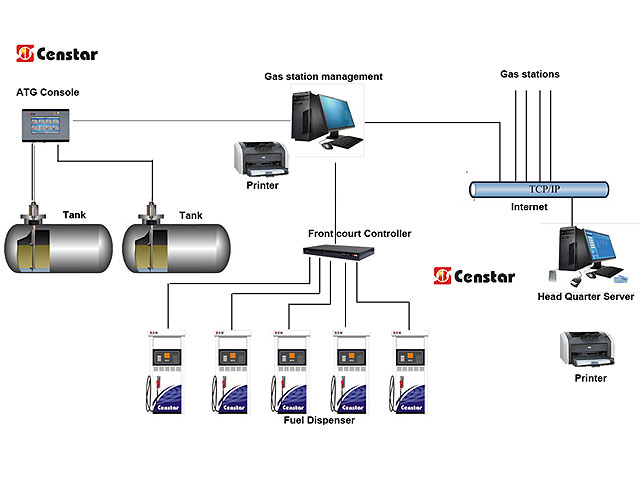

TLS 350 Series Automatic Tank Gauge for Optimal Risk

Censtar’s TLS 350 Series Automatic Tank Gauge provides optimal risk management and environmental protection for the whole forecourt. allowing unattended fuel delivery at any time, even when the station is closed.

Diesel Direct's Risk Management Practices for On site fueling

Risk management is the most essential part of the day to day operations at Diesel Direct. Our primary goal is to deliver our products in the safest and most efficient manner possible. In order to meet this goal we utilize many best practices:

Quantified Risk Assessment of Aircraft Fuelling Operations

Recently there have been a number of major fuel spills on the ramp at UK airports. Both the Health and Safety Executive (HSE) and the Civil Aviation Authority (CAA) were interested in establishing the level of risk posed by fuelling, aircraft maintenance and defuelling operations carried out on the ramp.

New Jersey Fuel Dispensing Facilities Compliance Calendar

Pre Construction Permit (PCP): Fueling stations can obtain a PCP if they want a fuel throughput limit which exceeds the limit of a general permit or if the facility is ineligible for a general permit. COST: $2527 for gasoline tank + $590 for each additional piece + $2527 Risk Assessment fee.

Commercial and Retail Fuel McPherson Oil Company

Here is a sampling: Budgetary Tools. Security and Supply. Multiple Purchasing Techniques and Consultation. Variable Risk Management. Vendor Managed Inventory. Fixed Fuel Pricing helping you lock in profit. Cellular Tank Monitoring ensuring you don’t run out of fuel.

Gasoline Quality: Retailer Risk Assessment Information

All diesel fuel dispensers must be clearly and conspicuously labeled to prevent customers from dispensing diesel fuel into gasoline engine vehicles. In some cases a diesel label on the nozzle housing itself would be beneficial.

Air Products Introduces Advanced Retail Hydrogen Fuel

Spring Lake, Michigan based Bennett Pump Company is a leader in engineering and manufacturing of fuel dispensing and integrated payment systems technology for retail and commercial applications including both traditional and alternative fuels.

Safety and Loss Prevention PT Risk Management

Mobile or skid tanks that are loaned or rented to large fuel operations create potential pollution liability exposure. An expert contract review by PT Risk Management could save you from being the responsible party in the event of physical damage to the tanks, or the need for a pollution cleanup.

FuelFocus Fuel Management Software Fuel Management System

FuelFocus is an automated fuel management software system that supports continuous, real time fuel management over virtually any communication platform. Its sophisticated combination of hardware and software provides accountability for metered or pulsed consumables, including gasoline, diesel, propane, CNG, LNG, hydrogen, glycol and lubricants.

Hydrogen Vechicles and Fuel Cells PDF

• Forklifts are equipped with fuel cells as a replacement for traditional battery packs. • A typical project consists of a refueling system (tank, compressor, piping, etc.) providing hydrogen to a dispenser located inside a warehouse. Forklift Equipped with Fuel Cells Typical Hydrogen Fueling Infrastructure (Courtesy of

FUEL DISPENSING, PETROLEUM PRODUCTS AND

Vendor must explain in detail its security for system billing, card control, fuel dispensing, and risk management. Vendor must submit its methodology for electronic data interchange with the existing "SAPA members'” computer configuration. Vendor must provide in detail, a plan for emergency dispensing of fuels in case of

FUELING AND FUEL MANAGEMENT/STORAGE FUEL

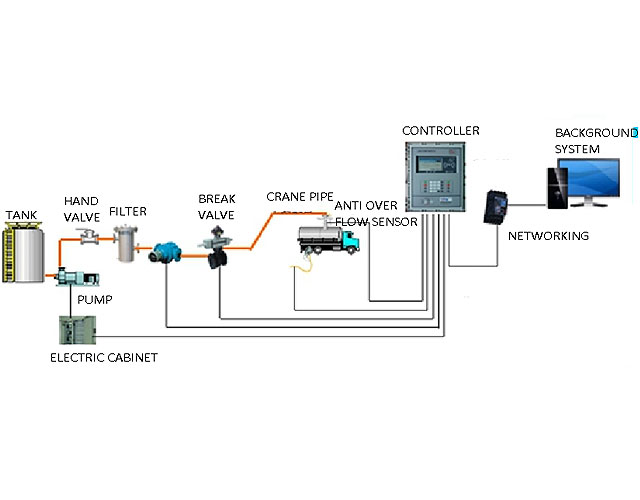

Fueling and Fuel Management/Storage Fuel Transfer and Transport Tank Trucks 4 (10) The fuel distribution operator hooks up the loading arm to the truck or the unloading arm to the tank if offloading. To catch any potential drips when disconnecting the loading/unloading arm, a five gallon spill bucket shall be placed beneath the hook up. All

Tokheim Fuel POS® TokheimTokheim

Forecourt control. Connect to all types of fuel dispensers on your forecourt with ease through a fully integrated digital pump controller. The risk of drive offs is reduced through built in alerts, integrated video imagery and through fuel prepayment features.

Quantifying Project Risk

Quantifying Project Risk Doug Nufer, MBA, PMP Program Director, onTrack Project Services Management onTrack Project Diesel Fuel 2 Dispenser Hose 3 Disperal Rate 3 Dispersal Measurement 3 Intercom 2 Internet Access 1 LED Display 2 Lengthy Swing around Hose 1 Mechanical Display 1 Multi Octane Single Pump Valve 2

Gasoline risk management: A compendium of regulations

This article summarizes current U.S. risk management measures for gasoline at selected stages in its lifecycle (see Fig. 1)—from the point where the gasoline is produced at a refinery, through its delivery at the retail station pump, and concluding with its use as a motor fuel. It highlights both regulatory controls and current industry standards and practices during the lifecycle.

Wayne Fueling Systems

Wayne Fueling Systems is a leading supplier of fuel dispensers, payment terminals, forecourt control devices, point of sale and measurement and control solutions to retail commercial fueling customers in over 140 countries.

Preventing Groundwater Contamination at Gas Stations—

The guiding principle of stormwater management at gas stations is to keep clean water clean. Relatively clean stormwater, such as from roofs and areas other than the fueling area, may not be allowed to run onto the fuel dispensing area (Env Wm (al)). The relatively clean

A Field Guide to Fuel Handling, Transportation & Storage

q Assess and manage the risk potential at all remote fuel cache locations. (See Section 7. Risk assessment.) q Ensure all empty containers are removed from remote locations and returned for refilling or recycling. 1.3 TRANSPORTATION Note: TDG documentation is not required when the total fuel capacity of all the containers on the vehicle is = 2000L.