tank gauging system purpose

level measurement and tank gauging systems SlideShare

Tank Gauging System • A generic name for the static quantity assessment of liquid products in bulk storage tanks • Data from Gauging Instrumentation transmitted to Inventory Management System to compute overall state (level, mass, density, volume) of Product inside the tanks.

Automatic Tank Gauging (ATG) North Dakota

Components of an Automatic Tank Gauging System. An ATG uses probes located in each tank or compartment to measure fuel and water levels. Each probe consists of a long rod with floats or sensors. The position of the floats tells the ATG console how much fuel and water are present in the tank.

Marine Sounding Equipment: How does sounding work?

In the same way, a ship’s fuel oil (bunker) tank or cargo oil tank has to be checked for its increase/decrease of its level during the operation of the ship/operations carried out on the ship. We will learn how does sounding work in context of ship tanks in this article and the use of

What is Automatic Tank Gauge? Definition from Petropedia

Automatic tank gauge (ATG) systems measure the levels of liquids inside tanks with the help of electronic probes. These probes consist of long rods that house certain number of sensors known as floats. The position of the floats informs the operator sitting at the ATG console about the amount of petroleum product present in the tank.

The importance of tank overfill protection

An effective tank overfill prevention program is key in protecting an organization against the many costs associated with a spill, as well as in ensuring employee and public safety. Owners and operators of tanks and wells should make overfill prevention a priority.

Tank Gauging & Associated Standards API OIML ISO

Provides guidance on the installation, commissioning, maintenance, validation, and calibration of hydrostatic tank gauging (HTG) systems for the direct measurement of static mass of liquid hydrocarbons in storage tanks. This edition is applicable to hydrostatic tank gauging systems that use pressure sensors with one port open to the atmosphere.

Interstitial & Secondary Containment Sensors Veeder Root

The Interstitial Sensor for steel tanks with high alcohol product detects the presence of liquid between the double walls of the tank. Learn More Non Discriminating Interstitial MicroSensor for Steel Tanks

Tank Gauging System From Level Measurement To Computer

This video describes how a Tank Gauging System works. The system consists of a custody transfer certified non contacting Radar Level Gauge. Temperature is me

Tank Gauging Basics Varec

A tank gauging system may be selected based on accuracy, repeatability or the ability to perform multiple measurements, such as temperature or density profiles. Tank gauges may not even be integrated into an inventory system, instead the gauge may only provide level outputs to alarm, relay or other host systems.

Tank Gauging Systems Radar Gauge Motherwell Tank Gauging

Our tank gauging systems are designed and manufactured in the UK and supported throughout the world by our team of Product Engineers and our international network of agents. We can trace our manufacturing back to the year 1859 when the Bold Iron Works was established by William Neill & Son Ltd in St Helens, England. The company specialised in

Gauging Systems Inc. (GSI) Liquid Bulk Storage Tank

Gauging Systems Inc. provides: Both bench and field service repair of tank gauging and related equipment. Project engineering and supervision for on site installations (retrofit or new equipment). Engineers (Communications, Electrical, Mechanical, and Software) available for system design and custom (OEM) product design.

Fuel gauge Wikipedia

Systems that measure large fuel tanks (including underground storage tanks) may use the same electro mechanical principle or may make use of a pressure sensor, sometimes connected to a mercury manometer. Many large transport aircraft use a different fuel gauge design principle.

TECHNOLOGY Review of tank measurement errors reveals

Simply put, one cannot determine the true water content of the material in a tank by collecting tank samples manually and measuring the depth of free water at the gauging well.

Modernizing Tank Gauging Systems via Emulation Emerson

In a Tank Storage magazine article, Gauge Emulation: a cost effective solution for tank gauging upgrade projects, Emerson’s Hans Westerlind shares how technology advancements make it possible to incrementally replace outdated mechanical level measurement devices with accurate electronic devices. Older tank gauging systems often had proprietary communications between the

Tank Temperature Measurement

Temperature gauging systems offer reliability, high tank temperature measurement accuracy, minimal maintenance cost and easy installation for all types of liquid bulk terminals and storage facilities.

Tank Gauges Field Instruments FuelsManager Software

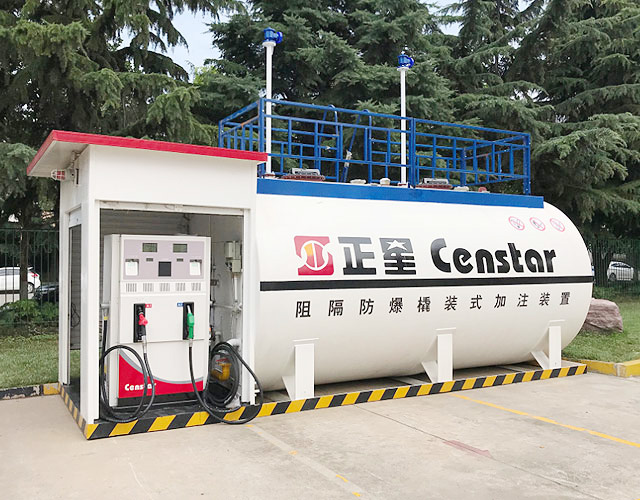

Tank gauging is the generic name given to the measurement of liquids (product) in bulk storage tanks with the aim of quantifying how much product is in the tank, “gauging the contents of a tank”. Today, the oil & gas industry uses the static measurement of the tank contents to account for product stored and product moved into and out of the tank.

Modernizing Tank Gauging Systems in Manageable Steps

A Tank Storage magazine article, Emulation: The Cost Effective Solution to Tank Gauging Upgrades, highlights a statistic of an estimated one million bulk liquids storage tanks in use across the globe. Many of these storage tanks use older, mechanical level measurement devices and tank gauging systems.

The Art of Tank Gauging

A tank gauging system is a very cost effective and accurate solution compared to flow metering systems, especially when high flow rates are present and large quantities are transferred.

Automatic Tank Gauging Products Veeder Root

Veeder Root provides highly customizable automatic tank gauge systems that provide compliance and fuel management solutions for petroleum site owners and operators around the world.

Tank Management Welcome to John H. Carter Company

Rosemount Tank Gauging Consider Tank Gauging a System Science The Rosemount Tank Gauging System is world leading in tank management, based on the reliable and maintenance free radar level gauges. The system can be designed for SIL 3 safety. The Rosemount solution integrates easily with your existing network, DCS or host computer system.